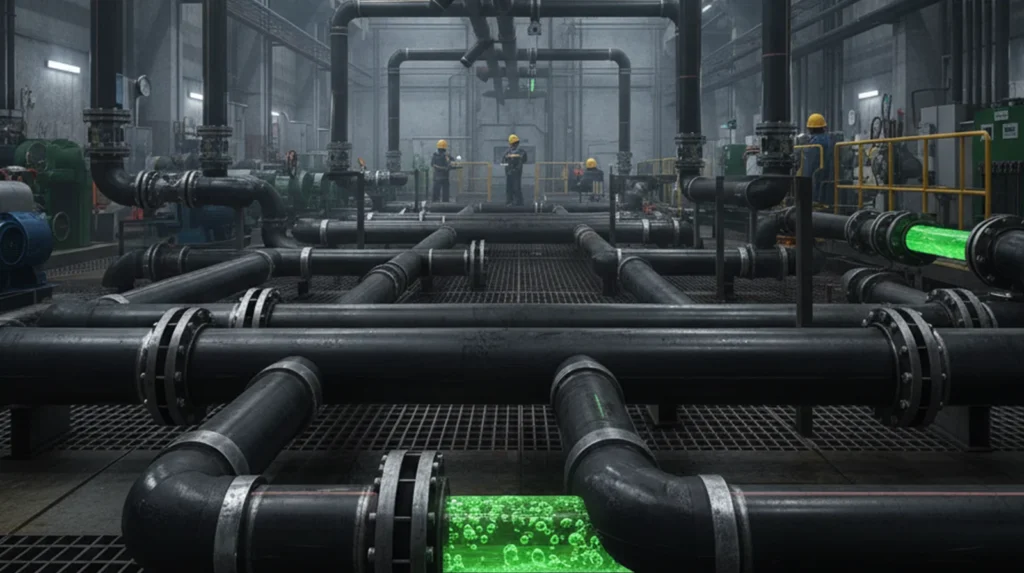

When it comes to industrial applications, choosing the best HDPE Pipe for Industrial Applications can be a daunting task. With numerous options available, how do you determine which one is the best fit for your project? Whether you are in manufacturing, mining, or water treatment, selecting the right HDPE (High-Density Polyethylene) pipe is critical to ensuring the durability, efficiency, and safety of your system.

HDPE Pipe for Industrial Applications are widely used due to their strength, flexibility, and resistance to corrosion. However, with varying grades, specifications, and installation methods, it’s easy to feel overwhelmed by the choices. In this article, we’ll break down the factors you need to consider when choosing the best HDPE pipe for your industrial applications.

By the end of this guide, you’ll understand key considerations such as pipe sizes, pressure ratings, installation techniques, and more, so you can make an informed decision that enhances the performance and longevity of your systems.

What is HDPE Pipe and Why is it Ideal for Industrial Applications?

HDPE, or High-Density Polyethylene, is a thermoplastic polymer commonly used in pipes for a range of industrial applications. It is favored in industries like water supply, wastewater management, oil and gas, and mining due to its durability and resistance to corrosion, chemicals, and extreme temperatures.

HDPE pipes offer several benefits for industrial use, including:

Corrosion Resistance: Unlike metal pipes, HDPE pipes do not rust or corrode over time.

High Impact Strength: They can withstand extreme pressure and mechanical stress without cracking or breaking.

Flexibility: HDPE pipes are highly flexible, which is beneficial for installations in areas where rigid pipes would fail.

Long Lifespan: When properly installed and maintained, HDPE pipes can last over 50 years, making them a cost-effective choice in the long term.

High-Quality Pipes & Fittings – Built to Last

Key Factors to Consider When Choosing HDPE Pipe for Industrial Applications

1. Pipe Size and Diameter: How Do You Determine the Right Size for Your Project?

One of the most critical factors to consider When Choosing HDPE Pipe for Industrial Applications is their size. The size depends on the flow rate, pressure requirements, and the type of fluid that will be transported through the pipes. Here’s a quick overview of what to consider:

Nominal Pipe Size (NPS): HDPE pipes are available in various sizes, typically ranging from ½ inch to 63 inches in diameter. The larger the diameter, the higher the flow rate the pipe can support.

Pressure Ratings: The pressure rating of the pipe is closely tied to its size. For industrial applications, pressure ratings generally range from PN6 (6 bar) to PN25 (25 bar).

Pro Tip: Consult with your project engineers to accurately calculate the required flow rate and pressure ratings. A pipe that is too small can lead to blockages or over-pressurization, while one that is too large may increase costs unnecessarily.

2. Pressure Rating: What Level of Pressure Will Your Pipe Be Under?

The pressure rating (also known as PN rating) determines how much pressure an HDPE pipe can safely handle. It is an essential factor for industrial applications, especially in systems that deal with high-pressure fluids, such as chemicals or water in industrial processes.

PN6 to PN10: Suitable for low-pressure applications, such as irrigation or potable water systems.

PN16 to PN25: Typically used in applications with moderate to high-pressure requirements, such as wastewater treatment, industrial cooling, and some oil and gas systems.

Pro Tip: Ensure that the pipe’s pressure rating aligns with the requirements of your system. Always account for potential pressure surges that could exceed the normal operational pressure.

3. Chemical Compatibility: Is the Pipe Resistant to Your Fluid’s Properties?

In industrial settings, pipes may come into contact with various chemicals and solvents. HDPE pipes offer excellent resistance to a wide range of chemicals, but it’s crucial to confirm that the specific material of the pipe is compatible with the chemicals being transported.

HDPE pipes are resistant to:

Acids and Bases

Oils and Solvents

Salts and Alkalis

For systems involving hazardous chemicals or high-corrosive fluids, you may need to select HDPE pipes with specialized additives or coatings for extra protection.

Pro Tip: Always check the chemical resistance charts provided by the manufacturer to ensure the pipe material can handle the substances in your application.

4. Temperature Resistance: How Hot or Cold Will Your Pipe Be Exposed To?

HDPE pipes are known for their excellent resistance to both low and high temperatures, but each pipe comes with specific temperature limits. Typically, HDPE pipes can handle temperatures from -40°C to 60°C, depending on the grade of the material.

Standard HDPE pipes are suitable for most industrial applications with ambient temperatures.

High-Temperature HDPE pipes are used in hot water systems or steam systems where higher temperatures are involved.

Pro Tip: If your application involves temperatures beyond the normal range, consult with the pipe manufacturer for temperature-resistant options or special coatings.

5. Installation Method: How Will the Pipes Be Installed?

The installation method you choose can affect the performance of the HDPE pipe. There are two primary methods for installing HDPE pipes in industrial applications:

Butt Fusion Welding: This method is ideal for joining larger diameter pipes (above 6 inches). It involves heating the pipe ends and fusing them together.

Electrofusion Welding: Used for smaller diameter pipes, this method uses an electrical current to melt the pipe ends and fuse them together.

Both methods create strong, leak-free joints, but choosing the appropriate technique depends on your pipe size and project requirements.

Pro Tip: For installations in remote locations or areas with challenging access, consider electrofusion welding for smaller pipes as it is more portable and requires less equipment.

6. Cost Considerations: Is the Price Right for Your Budget?

While HDPE pipes offer long-term savings due to their durability and low maintenance, the initial cost can vary based on the pipe size, pressure rating, and installation method. Some key factors that influence cost include:

Pipe Size and Quantity: Larger pipes and bulk orders will typically have a lower cost per unit.

Installation Costs: While HDPE pipes can reduce long-term maintenance costs, the installation cost can be high, especially if specialized equipment or skilled labor is needed.

Pro Tip: Consider the total cost of ownership over the lifetime of the pipe, including installation, maintenance, and potential replacements, rather than just the upfront cost.

7. Environmental Considerations: How Sustainable is Your Pipe Choice?

As industries become more environmentally conscious, it’s important to choose materials that support sustainability. HDPE is one of the most environmentally friendly pipe materials due to:

Recyclability: HDPE pipes can be recycled and reused, reducing waste.

Low Carbon Footprint: Compared to other pipe materials like PVC or metal, HDPE production involves lower carbon emissions.

Pro Tip: When possible, choose HDPE pipes that are manufactured using sustainable practices and offer certifications such as ISO 14001 for environmental management.

Conclusion: Making the Right Choice for Your Industrial Application

Choosing the best HDPE pipe for your industrial application requires careful consideration of size, pressure ratings, chemical compatibility, temperature resistance, installation method, and cost. With these factors in mind, you can ensure that you select the right pipe to enhance the efficiency, durability, and long-term success of your systems.

Remember, a well-informed decision will not only help your business save on maintenance costs but also contribute to more sustainable and efficient operations. Don’t hesitate to consult with experts and consider all the factors before making your purchase. With HDPE pipes, you are choosing a robust, flexible, and cost-effective solution for your industrial needs.

FAQ Section

1. What is the maximum pressure rating of HDPE pipes?

HDPE pipes can have pressure ratings up to PN25 (25 bar) for high-pressure applications, making them suitable for a variety of industrial applications.

2. Can HDPE pipes be used for transporting chemicals?

Yes, HDPE pipes are highly resistant to chemicals such as acids, oils, and alkalis. However, it’s essential to confirm that the specific HDPE grade is compatible with the chemicals in your system.

3. What temperature range can HDPE pipes handle?

Standard HDPE pipes can handle temperatures ranging from -40°C to 60°C. For higher temperatures, special HDPE pipes are available.

4. How do I install HDPE pipes?

HDPE pipes can be installed using butt fusion welding for larger pipes or electrofusion welding for smaller ones. Both methods ensure leak-free joints.

5. Are HDPE pipes environmentally friendly?

Yes, HDPE pipes are recyclable and have a low carbon footprint compared to other pipe materials like PVC or metal.

6. What is the lifespan of HDPE pipes?

When installed and maintained correctly, HDPE pipes can last over 50 years, making them a long-term investment for industrial applications.

7. How do I choose the right size for HDPE pipes?

The pipe size should match the required flow rate and pressure for your application. Consult with engineers to determine the optimal size based on your system’s specifications.