HDPE Pipes

HDPE Pipes & Fittings

High-Density Polyethylene Pipes Suppliers

Explore our extensive range of (high-density polyethylene) HDPE pipes & fittings, engineered to meet your diverse needs with unmatched durability and reliability. Our comprehensive range of high-density polyethylene (HDPE) and polypropylene random copolymer (PPRC) pipes, which includes the renowned DuraPE series, is expertly crafted to deliver outstanding resistance to abrasion and impact. This makes our pipes the ideal choice for a diverse array of applications, ranging from water supply and distribution systems to compressed air, chemicals, hazardous waste handling, slurries, mining, irrigation, and more. The exceptional durability and longevity of our HDPE and PPRC pipes make them the perfect solution, especially in remote areas.

With its adoption of innovation, our offerings incorporate advanced technology, like the butt-fusion welding machine, that provides welds without weld lines for absolute connections. In our offering portfolio, UPP Pipes also boasts as a state-of-the-art upgrade with amplified versatility and productivity of our pipe solutions. With NewTech-Pipes.com, we remain committed to offering surefire, enduring piping solutions suitable to changing industry requirements across multiple sectors.

Primary Application Areas

- Water Supply Systems – Used in distributing clean and safe drinking water to homes and businesses.

- Sewerage & Drainage – Ideal for wastewater management, stormwater systems, and industrial fluid disposal.

- Agriculture & Irrigation – Perfect for irrigation systems, farming needs, and well water applications.

- Telecommunications – Protects and organizes underground cables for telecom infrastructure.

- Construction Industry – Widely used in various construction projects for utility and fluid transport.

- Gas & Oil Transmission – Suitable for transporting natural gas, crude oil, and other fuels.

- Power & Chemical Plants – Reliable for handling chemicals and high-pressure fluids in power generation and industrial processes.

FEATURES & ADVANTAGES

- Economical solutions

- Joints resistant to leaks

- High resistance to fatigue

- Flexibility

- Strong seismic resistance

- Lightweight

- Easy to join

- Durable

- Ductile

- Excellent flow properties

- Sturdy in extreme weather conditions

- Wide operating temperature range (-30 to +60)

- Tear and pressure resistance

- Low flow noise

Compression Coupling Joint

Compression fittings are generally available for smaller pipe diameters. To connect the pipes, they are first cut perpendicular to their axis and then joined using a coupling adapter. Once the pipes are properly aligned in the adapter, the bolts are hand-tightened to create a secure connection.

However, for pipes with a diameter of 40mm or more, tightening the bolts by hand is not sufficient. In such cases, a special wrench should be used to ensure a firm and safe connection. It’s also important to note that for pipe sizes over 110mm in diameter, using this compression coupling method is not recommended.

HDPE Pipe Handling & Storage Safety Guidelines

To ensure the long-term durability and performance of HDPE pipes and fittings, it’s essential to follow proper safety and handling practices. At Newtech Pipes, we prioritize quality and safety at every step. Here are key safety measures you should follow when storing or transporting HDPE pipes:

Proper Storage

- Always store pipes flat on firm, level ground that can fully support their weight.

- Use non-metallic lifting slings—preferably made from polypropylene or nylon—to avoid damaging the pipes.

- Keep pipes and fittings safely covered using protective packaging to shield them from environmental exposure.

- Store away from direct sunlight or extreme heat for extended periods.

Avoid Potential Hazards

- Never allow pipes or fittings to come into contact with sharp or pointed objects.

- Keep all materials away from harsh chemicals that could cause surface damage or degradation.

- Do not drag, roll, or throw HDPE pipes during handling or unloading.

- Avoid using metal slings, chains, or hooks, which can scratch or puncture the surface.

Technical Specifications of PE 100 Pipe Dimension Conforming to ISO 4427, DIN 8074 Specifications:

| O.D [mm] | SDR 26 | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | SDR 7.4 |

| PN-6.3 | PN-8 | PN-10 | PN- 12.5 | PN-16 | PN-20 | PN-25 | |

| Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | |

| 20 | – | – | 2.3 | 2.3 | 2.3 | 2.3 | 3.0 |

| 25 | – | – | 2.3 | 2.3 | 2.3 | 3.0 | 3.5 |

| 32 | – | – | 2.3 | 2.4 | 3.0 | 3.6 | 4.4 |

| 40 | – | – | 2.4 | 2.9 | 3.7 | 4.5 | 5.5 |

| 50 | – | 2.4 | 3.0 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | 2.3 | 3.0 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | 2.8 | 3.7 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | 3.3 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | 12.3 | 15.1 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | 14.0 | 17.1 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.1 | 39.7 | 48.5 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | 69.5 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | – |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 | – | – |

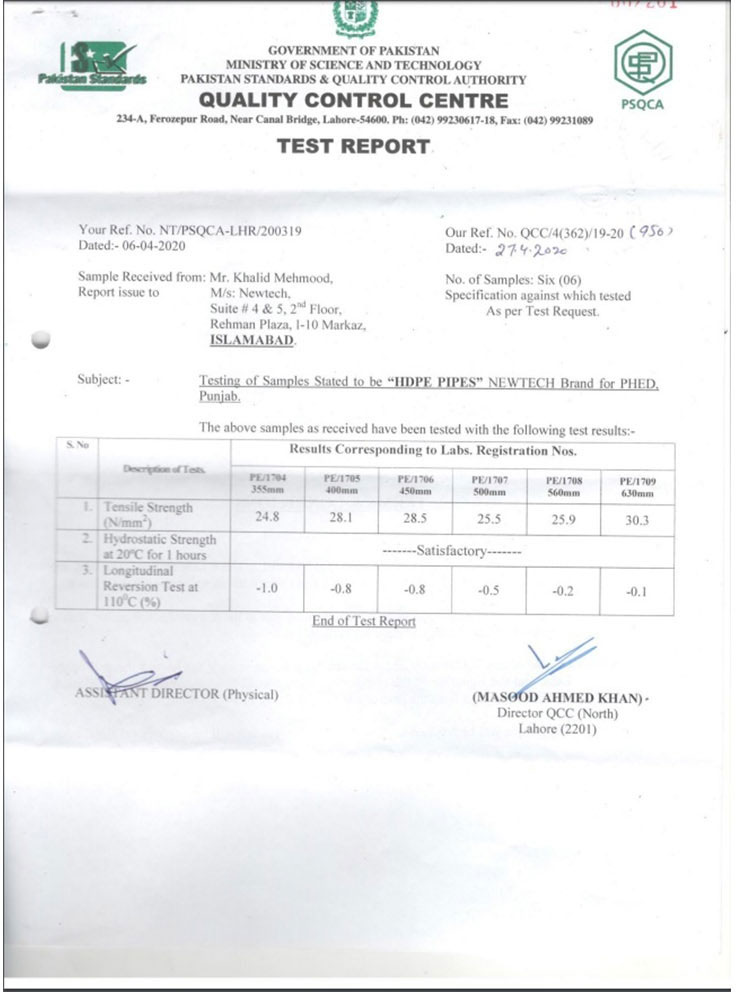

Typical Properties of (PE-100) polyethylene Pipe Material:

| CHARACTERISTICS | UNITS | VALUE |

| DENSITY | gm/cm3 | 0.95 |

| DESIGN STRESS | MPa | 8 |

| TENSILE STRENGTH AT YIELD | N/mm2 | 23 – 25 |

| FLEXURAL MODULES (BEND CREEP) | N/mm2 | 1000 – 1200 |

| ELONGATION AT BREAK | % | > 600 |

| CRYSTALLITE MELT RANGE | ° C | 128 – 132 |

| SURFACE RESISTANCE | O | > 1014 |

| COEFFICIENT OF LINEAR EXPANSION | mm/m*k | 0.13 |

| HEAT CONDUCTIVITY AT 20° C | W/m*K | 0.38 |

| IMPACT STRENGTH AT 23 DEG C | Kj /m2 | 83 |

| BRITTLENESS TEMPERATURE | °C | < -70 |

| SHORE HARDNESS | D | 62 |

| MELT FLOW RATE (Melt Flow Index) | g/10min | 0.15 |

| WATER ABSORPTION | % | 0.01 – 0.04 |

Why NEWTECH HDPE Pipes?

- Resistant to weather conditions

- Resistance to tearing and pressure

- High resistance to stress cracking.

- Light in Weight

- More Flexible than other metal-based pipe, such as – GI, Stainless Steel, Black Iron, and Copper etc.

- Coating of the HDPE pipe is quite smooth.

- Capable to resist from environmental threat or Crack

- It can defy pipeline Corrosion

- Can protect form Frost & Rodent.

- Hygienically Safe (Food Grade)

- Easy to install and handle.

- There is a least chance to conduct heat.

- Abrasion free

- Has Long Life (approx. 50 Years)

HDPE Compression Fittings

NEWTECH is providing all sizes of HDPE Compression Fittings. Sizes from 20mm to 110mm according to international standards.

We have our hands on one of the top compression fittings manufacturers in the world known as NORMA GROUP which produces compression fittings under the brand name of “FISH”. We are proud to been selected as their sole distributors in Pakistan due to our brand identity and sales turnover. These fittings are made according to ISO 4427 standards and comply with all international specification.

- Compression couplings (pipe-to-pipe joiner)

- Compression reducer fitting

- Compression 90⁰ elbows

- Compression tee with male offtake

- Compression tee with female off-take

- Compression reducing tee fitting

- Compression equal tee fitting

- Compression 90⁰ elbow with male threaded end

- Compression 90⁰ elbow with female threaded end

- Compression flange adaptor

- Compression end cap / end plug

- Compression male adaptor

- Compression female adaptors

Our compression fittings and clamp saddles are designed specifically for connecting polyethylene pipes with an outside diameter from 16 mm to 110 mm (200 mm for clamp saddles). They are compatible with PE80 and PE100 pipes complying with ISO 4427. They are normally used to convey drinking water and fluids at pressures up to 16 bar for generic applications. The quality of the materials used makes these FISH fittings resistant to etching by numerous chemical substances, and to UV-rays.

NEWTECH is providing HDPE Butt-Fusion Fittings ranging from 63mm to 630mm according to ISO standards. Our HDPE butt fusion fittings are one of the best in all over in Pakistan. Previously like many other manufacturers, we used to import these fittings from renowned European brands but now we are proud to introduce that we are the only ONE in this industry to establish BUTT FUSION fittings manufacturing plant in Pakistan with the brand name of “PLAST-1”.

ABOUT PLAST-1:

PLAST1 is one of the few new names in Pakistan’s Plastic pipes industry being getting immense recognition due to its quality products. The company is US registered and was established in 2016, after demand for quality HDPE fittings increased systematically. Today, it is a prominent player in the HDPE fittings manufacturing industry and has become synonymous with the term quality assurance. The company manufactures HDPE BUTT-FUSION fittings ranging from 63mm to 630mm. Rest assured, the raw materials are all imported from the finest suppliers worldwide so that our customers only experience the best of what we have to offer.

PLAST1 follows a process steeped with hard work and innovation. This is due to the adoption of certified integrated quality management systems in accordance with ISO 9001-2015 standards and a production control system in accordance with the ISO standards through periodic tests in accredited laboratories. PLAST1 has certification from Pakistan Standards and Quality Control Authority and Pakistan Engineering Council due to their knowledge of and integration with the plastic industry.

Our PE Butt-Fusion fittings ranges from 63mm to 630mm including:

- 90° Elbow.

- 45° Elbow.

- Equal Tee.

- Reducing Tee

- Reducer/ Reducing Socket.

- End Cap.

- Stud End/ Flange Adapter

HDPE Electro Fusion Fittings

The use of PE electro-fusion fittings with polyethylene pipes allows the creation of fully sealed PE pipe networks. With quality electrofusion fittings, plumbers and contractors across various industries can produce fusion-welded joints that offer reliability, flexibility and high performance.

All our Electro Fusion fittings are imported from World Renowned European brands according to international standards. Our electrofusion pipe fitting system offers high performance and ease of installation. Using the electrofusion technique, polyethylene pipes are conveniently joined, minimizing welding and cooling time. In each EF poly pipe fitting, the wires’ energizing coils of the electro fitting are precisely positioned ensuring uniform melting for a strong joint.

Our extensive range of PE electro-fusion pipe fittings include:

- Electrofusion Coupler or Joiners

- Electrofusion Reducer Fittings

- 90° Electrofusion Elbow Fittings

- 45° Electrofusion Elbow Fittings

- Electrofusion Reducing Tee

- Electrofusion Equal Tee

- Electrofusion Tapping Saddles

- Electrofusion Branch Saddles

- Electrofusion End Cap Fitting

- Electrofusion Test End Cap Fitting

- Brass Transition Fittings for EF Fittings

- Threaded PE Transition Fittings for EF Fittings

We also carry tools, accessories and equipment for electrofusion welding.

Looking for reliable, top-quality HDPE pipes and fittings? At NewTech-Pipes.com, we provide advanced piping solutions built to last. Whether you’re working on water supply systems, industrial projects, or hazardous waste management, our HDPE products deliver exceptional performance with superior resistance to impact and abrasion.

Engineered for long life and seamless installation, our pipes are compatible with advanced butt-fusion welding machines, ensuring strong, leak-free joints that stand the test of time. Explore our innovative DuraPE series and cutting-edge UPP pipes—perfect for demanding environments and remote area installations.

Join industry professionals around the globe who trust NewTech Pipes for durable, high-performance piping systems tailored to the evolving needs of modern infrastructure.

HDPE (High-Density Polyethylene) is a strong, flexible plastic material known for its excellent durability, chemical resistance, and long service life. It’s ideal for piping systems because it resists corrosion, handles pressure and extreme temperatures, and is suitable for both water and industrial applications.

HDPE pipes are widely used in:

- Water supply and distribution

- Sewerage and drainage systems

- Agricultural irrigation

- Gas and oil transmission

- Telecommunication cable protection

- Construction projects

- Industrial and chemical fluid transport

They are also great for use in remote or harsh environments due to their toughness and long lifespan.

HDPE pipes can be joined using butt-fusion welding, which creates a seamless, leak-proof connection by melting the pipe ends and fusing them together. Smaller pipes can also be joined using compression coupling joints, although this method is typically recommended for pipes under 110mm in diameter.

Yes! HDPE pipes are non-toxic and safe for potable water systems. They don’t leach harmful chemicals into the water, making them ideal for clean and safe water distribution to homes and businesses.

HDPE pipes offer several key benefits:

- Long-lasting durability (over 50 years in many cases)

- Corrosion and chemical resistance

- Flexibility and shock absorption

- Lightweight and easy to transport

- Leak-proof joints through butt-fusion

Excellent flow performance due to smooth internal surface

Absolutely. HDPE pipes are designed for high-pressure systems and can operate within a wide temperature range of -30°C to +60°C, making them suitable for both cold and hot climates.

When handling HDPE pipes:

- Store them on flat, solid ground

- Avoid sharp objects and contact with chemicals

- Use non-metallic slings for lifting

- Don’t drag or drop pipes

- Keep away from prolonged exposure to intense heat

For more details, visit our Handling & Storage Guidelines section above.

The DuraPE series by NewTech Pipes is an advanced range of HDPE pipes known for enhanced strength, flexibility, and performance. It’s specially engineered for high-stress environments like mining, industrial plants, and remote area installations.

Yes! We provide advanced butt-fusion welding machines that deliver clean, reliable joints with no weld lines. This ensures your pipeline is both leak-proof and long-lasting.

At NewTech Pipes, we combine innovation with reliability. Our HDPE and PPRC pipes are built to meet global standards, offering top-tier performance for diverse industries. We also offer expert support, fast delivery, and competitive pricing—making us a trusted partner in modern piping solutions.

Recent Posts

- The Role of PPRC Pipes in Building Eco-Friendly Plumbing Networks

- HDPE Pipes Explained: Applications, Pricing & Durability Guide

- PVC Pipe Rate List 2025 in Pakistan: Complete Buyer’s Insight

- Why Should You Use Super Flo PPRC Pipes at Home?

- Why MDPE Pipes Are Ideal for Gas and Water Networks in Pakistan