Discover the best HDPE pipes in Pakistan at NewTech-Pipes.com — designed for water, gas, industrial, and agricultural systems. Our guide explains HDPE pipe features, applications, pricing, and joining techniques. Get reliable, eco-friendly, and affordable piping for modern infrastructure.

What makes HDPE pipes essential for modern infrastructure?

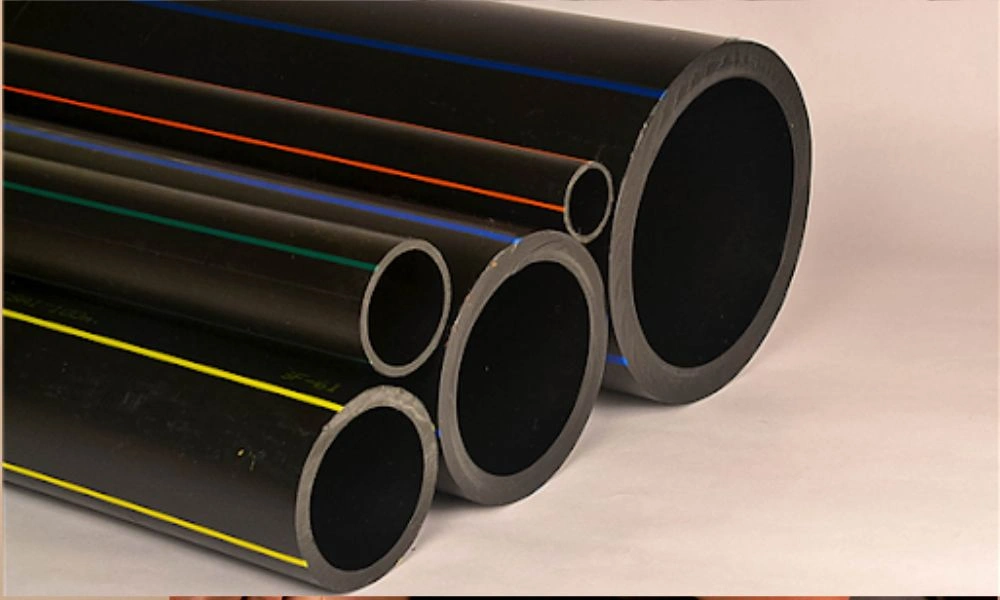

High-Density Polyethylene (HDPE) pipes are now a staple of contemporary infrastructure because of their high level of flexibility, durability, and affordability. Made from thermoplastic polymers derived from petroleum, HDPE pipes provide a strong yet light choice for water, gas, and other industries’ fluid transport. In Pakistan, there has been a rapid growth in the use of HDPE piping systems, serving multiple industries like agriculture, construction, and urban services.

This in-depth guide explores the characteristics, uses, cost, quality testing, and joining techniques of HDPE pipes and is an invaluable resource for contractors, engineers, and homeowners.

What Are HDPE Pipes?

HDPE pipes are flexible plastic tubes manufactured from high-density polyethylene, a thermoplastic polymer which has a high strength-to-density ratio. HDPE pipes are made by heating the polymer to a molten state and shaping it into the form of the desired pipe using extrusion, with subsequent cooling and stringent quality checks.

Characteristics of HDPE Pipes

Longevity: HDPE pipes have a life span of over 50 years under regular conditions, so they are the go-to option for a long-term investment in infrastructure projects.

- Flexibility: Their intrinsic flexibility enables fitting into uneven ground with fewer joints, minimizing the likelihood of leaks.

- Corrosion Resistance: In contrast to metal pipes, HDPE pipes are not susceptible to rust and corrosion even under aggressive conditions.

- Chemical Resistance: HDPE pipes are resistant to exposure from a diverse array of chemicals and hence are ideal for use in industry.

- Lightweight: Being much lighter than conventional material steel, HDPE pipes are simpler to transport and install.

- What makes HDPE pipes essential for modern infrastructure? is recyclable and non-toxic, thus supporting sustainable development goals.

Use of HDPE Pipes

The applicability of HDPE pipes renders them ideal for different uses in different industries:

1. Water Supply System

HDPE pipes are used extensively to distribute potable water owing to their non-toxicity and corrosion resistance. Their flexibility and leak-proof connections guarantee a safe water supply in both rural and urban areas.

2. Sewer and Drainage System

In sewer and drainage systems, HDPE pipes provide exceptional performance through leak-tight joints and chemical degradation resistance. They are well suited for buried applications where soil settlement and corrosive materials are issues.

3. Gas Distribution

HDPE pipes are used in gas distribution systems owing to their high strength, flexibility, and impermeability. They are capable of supporting high-pressure gas transmission with minimal leakage risk.

4. Industrial Piping

Industries use HDPE pipes for the transportation of chemicals, slurry, and other industrial liquids. Their abrasion and chemical resistance makes them long-lasting and safe in corrosive industrial environments.

5. Agricultural Irrigation

Agricultural irrigation systems use HDPE pipes, including drip and sprinkler systems. Due to their light weight and ease of installation, they are the best choice for large agricultural fields.

6. Fire Fighting Systems

HDPE pipes are ideal for fire suppression systems because they can withstand high pressure and are long-lasting. They can be safely used to transport water or fire-retardant chemicals during emergencies.

Evaluating the Quality of HDPE Pipes

Maintaining the quality of HDPE pipes is essential for long-lasting and safe piping systems. The following are some of the important considerations:

1. Certifications

Ensure that the pipes meet the national and international standards including:

Pakistan Standards (PSI)

2. Verification of Material Grade

Verify the pipes are constructed from virgin-grade HDPE material. PE80 and PE100 are common grades, with PE100 having greater strength and durability. Request a Material Test Certificate (MTC) to verify the material grade.

3. Visual Inspection

Inspect the pipes for a smooth inner and outer surface. Check for any cracks, bubbles, or discoloration, which could be signs of manufacturing defects.

4. Pressure Testing

Perform hydrostatic pressure tests to check that the pipes have enough strength to withstand operating pressures without leakage. Quality suppliers usually do these tests prior to delivery.

5. Flexibility and Tensile Strength

High-quality HDPE pipes must be flexible and not crack when subjected to stress. PE100 pipes, for example, must possess a tensile strength of not less than 40 MPa.

6. UV Resistance

For use in the outdoor environment, ensure that the pipes are UV-stabilized or have carbon black to resist breakdown due to exposure to sunlight.

7. Documentation

Demand full documentation, such as production codes, material certifications, and test reports, to ensure the authenticity and quality of the pipes.

Joining HDPE Pipes to Steel Pipes

Fusion of HDPE pipes with steel pipes needs special techniques to meet the different material characteristics:

1. Flanged Connections

This involves the addition of flanges to each of the HDPE as well as the steel pipes, which are bolted together. This is ideal for applications with high pressure and easy maintenance by disassembling.

2. Mechanical Couplings

Mechanical couplings are sleeve connectors that connect HDPE to steel pipe without welding. They have accommodation for movement and thermal expansion, so they are the best for temporary or emergency installations.

3. Transition Fittings

Transition fittings are special fittings with one end designed for HDPE and the other for steel, offering a firm, long-lasting seal. They are widely used in repairing or adding extensions.

4. Electrofusion Fittings

Electrofusion is a process of using heat and pressure to join an HDPE pipe with a steel adapter in a durable, leak-free joint. Electrofusion needs specialized equipment and trained operators.

Note: It is always best to adhere to manufacturer recommendations and utilize piping experts when splicing HDPE to steel pipes to achieve safety and performance.

Why Use NewTech for HDPE Pipes?

NewTech ensures delivering high-quality HDPE piping solutions that are up to international standards. Our pipes are designed with virgin-grade materials, providing long-lasting durability, flexibility, and resistance to the environmental factors. For water supply, gas distribution, or industrial purposes, NewTech provides robust products along with expert advice and prompt delivery.