Have you ever wondered how essential HDPE pipes are in ensuring leak-free installations for plumbing, gas lines, and water distribution systems?

Whether you’re managing a large construction project or maintaining an industrial system, the need for a durable, leak-resistant pipeline system is undeniable. However, achieving that quality can often come down to one key factor: HDPE pipe welding.

Imagine this: you’re in the middle of a crucial installation, and you realize that the pipe joints might fail under pressure. This could lead to costly repairs, delays, and a whole host of headaches. But there’s good news! Mastering HDPE pipe welding can help you avoid these pitfalls and ensure a long-lasting, leak-free installation. In this guide, we’ll explore everything you need to know about HDPE pipe welding, offering expert insights and actionable advice for your next project.

What is HDPE Pipe Welding?

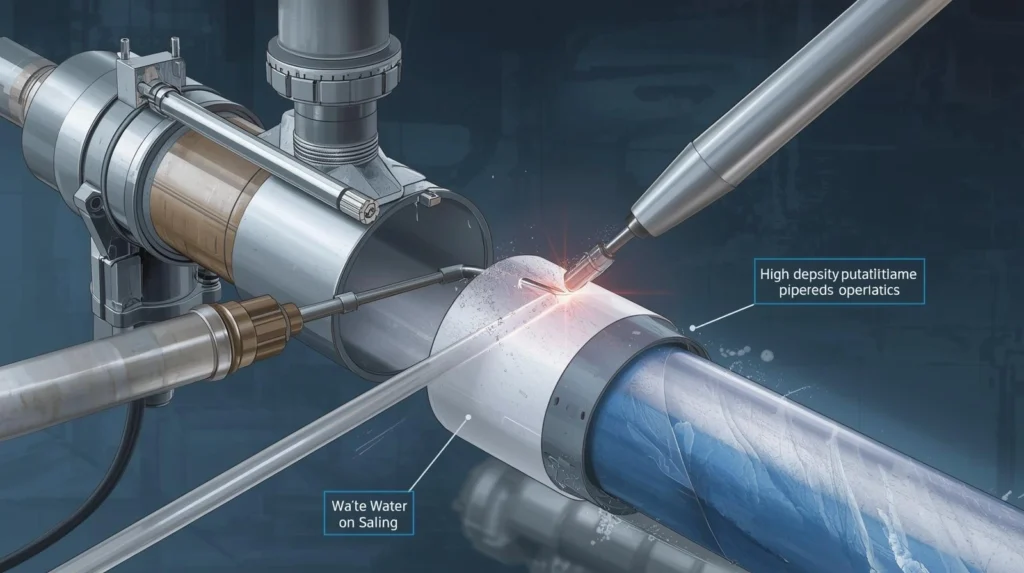

HDPE pipe welding is a process used to join sections of HDPE pipe to create continuous, leak-proof systems. HDPE pipes are widely used due to their flexibility, durability, and resistance to corrosion. The welding process creates a strong bond between two pipe ends, ensuring a tight and secure seal. This is critical in applications where leaks are unacceptable, such as water, gas, and sewer lines.

There are several welding methods, each suited to different situations. The two most common techniques are Butt Fusion Welding and Electrofusion Welding, each offering specific advantages depending on the project’s requirements.

Pro Tip:

Ensure that the welding is done under the right environmental conditions. Too much humidity or extreme temperatures can interfere with the welding process, leading to weaker joints.

Why is HDPE Pipe Welding Important for Leak-Free Installations?

One of the biggest challenges with piping systems is ensuring that the joints are free from leaks. Leaking joints can lead to water wastage, environmental contamination, and costly repairs. For HDPE pipe installations, welding creates a homogeneous joint, meaning the welded area becomes as strong as the rest of the pipe. This eliminates the common risks associated with threaded or glued connections, which can degrade over time and become prone to leaks.

By using HDPE welding techniques, you’re essentially creating an unbreakable seal, making your system much more reliable. Moreover, these welded joints are more resistant to pressure, temperature variations, and environmental factors like soil movement.

Pro Tip:

Before welding, inspect the pipe ends for any contaminants or debris. Clean ends create cleaner welds, reducing the chances of leaks.

What Are the Different HDPE Pipe Welding Techniques?

There are several methods of welding HDPE pipes, each with its own application and benefits. Here’s a breakdown of the most commonly used techniques:

1. Butt Fusion Welding

This is the most common method for HDPE pipe welding and is typically used for pipes of larger diameters. The process involves aligning two pipe ends and heating them with a special machine until the surface becomes molten. Once the ends are sufficiently heated, they are pressed together under pressure, allowing the plastic to fuse and cool.

- Ideal for: Larger diameter pipes (typically 2 inches and above)

- Advantages: Strong, durable welds; simple, reliable method

- Limitations: Requires specialized equipment and skilled operators

2. Electrofusion Welding

Electrofusion welding involves inserting a special coupler or fitting that has built-in electric heating elements. These elements heat the ends of the pipe and fuse them together. This method is often used for smaller pipes or in tight spaces where butt fusion welding may not be possible.

- Ideal for: Smaller pipes and confined spaces

- Advantages: Great for precise applications; suitable for installation without heavy machinery

- Limitations: More expensive fittings; less suitable for large diameter pipes

3. Socket Fusion Welding

Socket fusion welding is similar to butt fusion, but in this case, one pipe end is inserted into a matching socket fitting that is heated. Once the pipe and socket are melted, they are pressed together to form a bond.

- Ideal for: Small to medium pipes (1/2 inch to 4 inches)

- Advantages: Simple and cost-effective

- Limitations: Less suitable for larger installations

Pro Tip:

When selecting the welding method, always consider the pipe size, environmental conditions, and project timeline. Each method has specific strengths depending on the application.

How to Weld HDPE Pipes: Step-by-Step Guide

Welding HDPE pipes is a process that requires attention to detail, precision, and safety. Here’s a basic step-by-step guide to butt fusion welding, one of the most common HDPE welding methods.

Step 1: Preparation

- Clean the Pipe Ends: Ensure the pipe ends are free from dirt, dust, or grease.

- Align the Pipes: Place the pipes in the fusion machine to ensure they’re perfectly aligned. Misalignment can cause weak joints.

Step 2: Heating the Pipes

- Insert the Pipe Ends: Place both pipe ends into the heating plates.

- Set the Temperature: Typically, the heating plates are set to around 400°F (204°C), depending on the pipe’s thickness.

- Wait for Melting: Allow the pipe ends to heat for the required time until they are molten.

Step 3: Joining the Pipes

- Press the Pipe Ends Together: Once the pipes have reached the correct molten state, quickly press them together under a predetermined pressure. Hold for the appropriate time to allow the plastic to cool and bond.

Step 4: Cooling and Inspection

- Allow the Joint to Cool: The welded joint should be left to cool under pressure for a few minutes.

- Inspect the Weld: Check for any defects like misalignment, air bubbles, or weak spots. A properly fused joint will look smooth and uniform.

Pro Tip:

Always conduct a test weld before starting on the actual project to ensure your equipment is set up correctly.

Common Mistakes in HDPE Pipe Welding and How to Avoid Them

While HDPE welding is relatively straightforward, there are some common mistakes that can lead to poor-quality joints or even system failure. Here are a few to watch out for:

1. Inadequate Cleaning of Pipe Ends

Contaminants on the pipe surface can interfere with the welding process, leading to weak joints. Always ensure that the pipe ends are clean and dry before welding.

2. Improper Heating Time or Temperature

Each pipe and welding machine requires specific temperature settings. Too much heat can cause the pipe to burn, while too little heat can prevent the weld from fusing properly.

3. Misalignment of Pipes

Proper alignment is crucial to ensure a strong, leak-free weld. Misalignment can result in an uneven joint that’s prone to failure.

Real-World Example: Successful HDPE Pipe Welding in Water Treatment

In one large-scale water treatment plant project, the use of butt fusion welding enabled the installation of a 20-inch HDPE pipeline to transport treated water. The welded joints were tested under high-pressure conditions, and the results showed zero leaks, despite significant temperature fluctuations. By opting for HDPE welding, the project saved both time and money while ensuring system reliability.

Conclusion

HDPE pipe welding is a crucial process for creating reliable, leak-free installations in water, gas, and sewer systems. Understanding the different welding techniques and how to properly execute them will set your projects up for success. Whether you’re working with large or small diameter pipes, mastering the right welding technique ensures the longevity and durability of your system.

Now that you know the ins and outs of HDPE pipe welding, it’s time to apply this knowledge to your next project. Ready to tackle a welding job? Make sure to follow the steps, avoid common mistakes, and use the appropriate welding method for your application.

Pro Tip:

Remember, a little investment in the right welding equipment and training can go a long way in avoiding leaks and ensuring the quality of your pipe installations.

FAQ Section

1. What is the best method for welding small-diameter HDPE pipes?

For smaller pipes (1/2 inch to 4 inches), socket fusion welding is usually the best method as it’s simple, cost-effective, and works well in confined spaces.

2. Can HDPE pipe welding be done in cold weather?

Yes, HDPE pipe welding can be done in cold weather, but it requires careful temperature control. The pipes and welding equipment should be warmed to the optimal temperature before starting the weld.

3. How long does it take for HDPE pipe welds to cool?

Cooling times vary based on the pipe size and environmental conditions, but generally, a joint should be left under pressure for about 5-10 minutes to ensure a solid bond.

4. What are the common signs of a bad HDPE weld?

Signs of a bad weld include visible cracks, air bubbles, poor alignment, and an uneven weld surface. Always check for these issues before continuing with your installation.

5. Is HDPE welding a difficult skill to learn?

HDPE welding requires some practice and experience, especially with more advanced techniques like butt fusion. However, with proper training and attention to detail, anyone can master it.

6. Can HDPE pipes be welded underwater?

Yes, HDPE pipes can be welded underwater, but it requires specialized equipment and techniques to maintain the correct heating and pressure.

7. What is the lifespan of HDPE pipe welds?

When properly welded, HDPE pipe joints can last for 50-100 years, depending on the environmental conditions and the quality of the weld.