When choosing the right piping material for construction, infrastructure projects, or industrial applications, understanding the differences between available options is crucial. If you’ve ever been confused between UPVC pipes and HDPE pipes, you’re not alone. Many business owners, engineers, and construction professionals face this decision, as each material offers distinct advantages and drawbacks. The decision, however, can make or break a project in terms of cost, performance, and long-term sustainability.

To guide you through this, we will break down the essential characteristics of UPVC pipes, explore how they compare with HDPE pipes, and help you determine which material suits your needs the best. By the end of this blog, you’ll have a solid understanding of both materials and how to make an informed decision based on your specific project needs.

What Are UPVC Pipes?

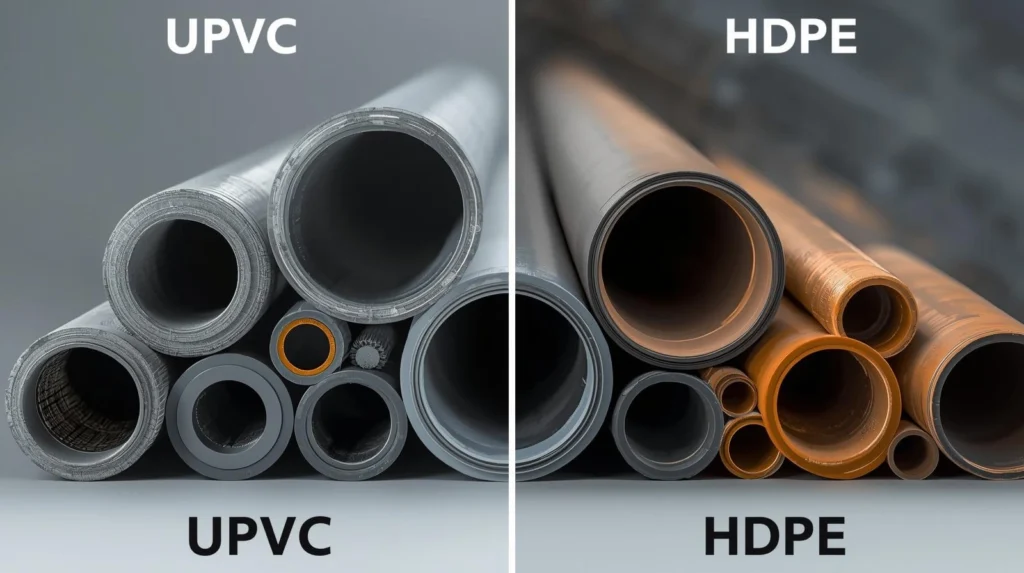

Unplasticized Polyvinyl Chloride (UPVC) pipes, also known as rigid PVC pipes, are a type of plastic pipe that is commonly used in plumbing, drainage, and irrigation systems. UPVC is durable, corrosion-resistant, and lightweight, making it an ideal choice for a variety of applications, including both residential and industrial uses. Unlike standard PVC pipes, UPVC pipes do not contain plasticizers, making them more rigid and suitable for applications that require structural integrity.

Key Features of UPVC Pipes

- Corrosion-Resistant: UPVC pipes are immune to rust, corrosion, and scaling, which can significantly extend the life of your infrastructure.

- Lightweight: UPVC is much lighter than metal pipes, making installation easier and more cost-effective.

- Non-Toxic: UPVC pipes are safe for drinking water systems, as they do not leach harmful substances.

- Long-lasting: With proper installation, UPVC pipes can last for decades without degradation.

What Are HDPE Pipes?

High-Density Polyethylene (HDPE) pipes are another popular choice for piping systems. They are known for their flexibility, strength, and resistance to a variety of environmental factors, including high-pressure systems, chemicals, and extreme weather conditions. HDPE is often used in applications such as water distribution, gas pipelines, and sewage systems.

Key Features of HDPE Pipes

- Flexible and Strong: HDPE pipes are flexible, allowing for easier installation in complex environments. Their durability makes them ideal for high-pressure applications.

- Chemical and Corrosion Resistance: HDPE pipes are resistant to corrosion, chemicals, and UV rays, making them suitable for both outdoor and underground use.

- Environmentally Friendly: HDPE is 100% recyclable, making it a more sustainable option than many other materials.

- Leak-Free: The fusion welding technique used in HDPE pipe installation creates leak-free joints, which ensures the system’s integrity over time.

How Do UPVC Pipes Compare to HDPE Pipes?

When comparing UPVC and HDPE pipes, the key differences come down to material properties, installation processes, costs, and suitability for specific applications.

1. Material Strength and Durability

- UPVC Pipes: These are rigid and offer excellent tensile strength, making them suitable for applications requiring structural integrity, such as plumbing and water supply systems.

- HDPE Pipes: HDPE pipes are much more flexible than UPVC, allowing them to handle higher stress and pressure fluctuations. Their flexibility also makes them suitable for use in areas with frequent ground movement, such as seismic zones.

2. Resistance to Corrosion and Chemicals

- UPVC Pipes: While UPVC is resistant to corrosion, it can become brittle and may degrade when exposed to UV light over long periods.

- HDPE Pipes: HDPE pipes outperform UPVC in terms of chemical resistance. They can withstand exposure to a wide range of aggressive chemicals, making them ideal for industries such as mining and wastewater treatment.

3. Installation and Maintenance

- UPVC Pipes: UPVC installation is straightforward and typically involves joining pipes using solvent cement. However, the rigidity of the pipes means they are more vulnerable to physical damage during installation.

- HDPE Pipes: HDPE pipes are often installed using fusion welding, which creates a seamless, leak-proof joint. The flexibility of HDPE pipes also reduces the likelihood of damage during installation.

4. Cost and Budget

- UPVC Pipes: UPVC pipes are generally more affordable than HDPE, making them the go-to option for budget-conscious projects that require a reliable, long-lasting solution for plumbing and irrigation.

- HDPE Pipes: Although HDPE pipes are more expensive than UPVC, their superior durability and performance in high-pressure or challenging conditions make them worth the investment for certain applications.

5. Environmental Impact

- UPVC Pipes: While UPVC is durable and long-lasting, it is not as environmentally friendly as HDPE. It is not biodegradable, and recycling options can be limited.

- HDPE Pipes: HDPE pipes are 100% recyclable, making them an environmentally superior option. The material also has a lower carbon footprint during production compared to UPVC.

6. Typical Applications

- UPVC Pipes: Best suited for low-pressure water supply, irrigation, drainage, and sewerage systems.

- HDPE Pipes: Ideal for high-pressure systems, gas pipelines, industrial applications, and environments with extreme conditions, such as areas prone to earthquakes.

Real-World Examples of UPVC and HDPE Pipe Usage

Case Study 1: UPVC Pipes in Residential Plumbing

In many residential buildings, UPVC pipes are used for cold water supply and waste water systems. Their corrosion resistance and ease of installation make them a cost-effective choice for homeowners. A study in Florida found that UPVC pipes last up to 50 years in non-extreme environments without requiring replacement or significant maintenance.

Case Study 2: HDPE Pipes in Water Distribution

In Lahore, Pakistan, HDPE pipes were used for an extensive water distribution system upgrade. The flexibility and chemical resistance of HDPE made it an ideal choice for the city’s aging infrastructure, allowing for faster and more durable installations. The project successfully reduced water loss and increased the system’s lifespan.

Case Study 3: HDPE Pipes in Mining

The mining industry in Australia has seen a significant shift towards using HDPE pipes for transporting slurry and chemicals. The durability, strength, and resistance to corrosive materials make HDPE the preferred choice for this challenging environment. A major mining operation reported a reduction in maintenance costs by 40% after switching to HDPE pipes.

High-Quality Pipes & Fittings – Built to Last

Conclusion

When deciding between UPVC pipes and HDPE pipes, it’s crucial to evaluate your specific needs and project requirements. UPVC pipes excel in low-pressure water systems and are a more budget-friendly option for standard residential and industrial applications. On the other hand, HDPE pipes offer superior performance in high-pressure, corrosive, and challenging environments, making them ideal for gas pipelines, mining, and large-scale infrastructure projects.

In summary:

- Choose UPVC pipes if you need a cost-effective, corrosion-resistant solution for standard plumbing and irrigation.

- Opt for HDPE pipes if you require flexibility, chemical resistance, or need a durable option for high-pressure systems and industrial applications.

Call to Action: Interested in learning more about how UPVC and HDPE pipes can be incorporated into your next project? Contact our team today for expert consultation and tailored recommendations.

FAQ Section

1. What is the difference between UPVC and PVC pipes?

UPVC (Unplasticized PVC) is a rigid form of PVC that does not contain plasticizers. It is stronger and more durable compared to regular PVC pipes, which are more flexible.

2. Can UPVC pipes be used for hot water systems?

No, UPVC pipes are designed for cold water systems. For hot water applications, CPVC (Chlorinated Polyvinyl Chloride) pipes are typically used.

3. Are HDPE pipes suitable for drinking water systems?

Yes, HDPE pipes are safe for potable water applications. They do not leach chemicals, making them ideal for water distribution systems.

4. What are the main benefits of using HDPE pipes in industrial applications?

HDPE pipes offer high chemical resistance, flexibility, and durability, making them the best choice for industrial applications that involve harsh chemicals or high-pressure conditions.

5. How long do UPVC and HDPE pipes last?

UPVC pipes can last up to 50 years, while HDPE pipes can have a lifespan of over 100 years when properly maintained.

6. Which pipe material is more environmentally friendly?

HDPE pipes are more environmentally friendly as they are 100% recyclable, whereas UPVC pipes are less commonly recycled.

7. Are HDPE pipes easy to install?

Yes, HDPE pipes are easy to install using fusion welding, creating seamless and leak-proof joints, which reduces the risk of installation errors.