Are you struggling to select the right uPVC pipes for your high-pressure plumbing system?

You’re not alone. With so many options available, it’s easy to feel overwhelmed by the choices. Whether you’re managing a commercial building or upgrading a residential plumbing system, the pressure on your pipes can be immense. Selecting the wrong material or size can lead to costly leaks, repairs, and potential system failure.

In this guide, we’ll break down everything you need to know about selecting the right uPVC pipes for high-pressure systems. We’ll cover essential factors such as pressure ratings, durability, and installation techniques. By the end of this post, you’ll have a clear understanding of how to make the best decision for your plumbing needs.

What is uPVC, and Why is it Ideal for High-Pressure Plumbing Systems?

uPVC (Unplasticized Polyvinyl Chloride) pipes are made from a type of plastic that is rigid and highly resistant to corrosion, making them a popular choice for various plumbing applications, especially in high-pressure systems.

Why uPVC Pipes Work Well in High-Pressure Systems

uPVC pipes are particularly well-suited for high-pressure environments because of their ability to handle significant internal pressure without deforming. Unlike other materials like PVC or metal, uPVC offers:

- High Strength-to-Weight Ratio: uPVC pipes are lighter than metal alternatives, reducing installation costs and effort.

- Resistance to Chemical Corrosion: Ideal for environments where water may have a high concentration of chemicals or minerals.

- Low Maintenance: Once installed, uPVC requires very little upkeep, making it cost-effective in the long run.

In high-pressure applications, uPVC’s rigidity and resistance to external pressures ensure longevity and reliability.

How to Determine the Right Pressure Rating for uPVC Pipes?

Understanding Pressure Ratings

The pressure rating of uPVC pipes is one of the most important factors to consider. This rating determines the maximum pressure the pipe can safely handle. It is typically measured in Bar or PSI (pounds per square inch). You should choose pipes with a pressure rating higher than the expected pressure in your system to avoid failures.

Key Points to Consider:

- Standard uPVC Pipes: Often have pressure ratings from 6 Bar to 16 Bar.

- High-Pressure uPVC Pipes: For applications requiring higher pressures (above 16 Bar), uPVC pipes with enhanced formulations or thicker walls are necessary.

For instance, a plumbing system in a multi-story building requires pipes that can withstand higher pressures due to water pumping from lower to upper floors. Opting for uPVC pipes with a higher pressure rating ensures durability and functionality.

What is the Ideal Pipe Size for High-Pressure Plumbing?

Pipe Size Matters

Choosing the right pipe size is critical when dealing with high-pressure plumbing systems. If the pipe diameter is too small, water will be forced through with excessive pressure, potentially causing bursts or leaks. If the pipe is too large, the system will waste energy, reducing efficiency.

Factors Affecting Pipe Size:

- Flow Rate: Larger pipes are needed for systems that require higher flow rates, such as in commercial buildings or agricultural systems.

- Pressure Loss: Ensure that the pipe size helps maintain optimal water pressure across the system by reducing friction and minimizing energy loss.

A good rule of thumb is to choose a pipe size that accommodates the required flow rate without causing significant pressure loss or compromising on the structural integrity of the system.

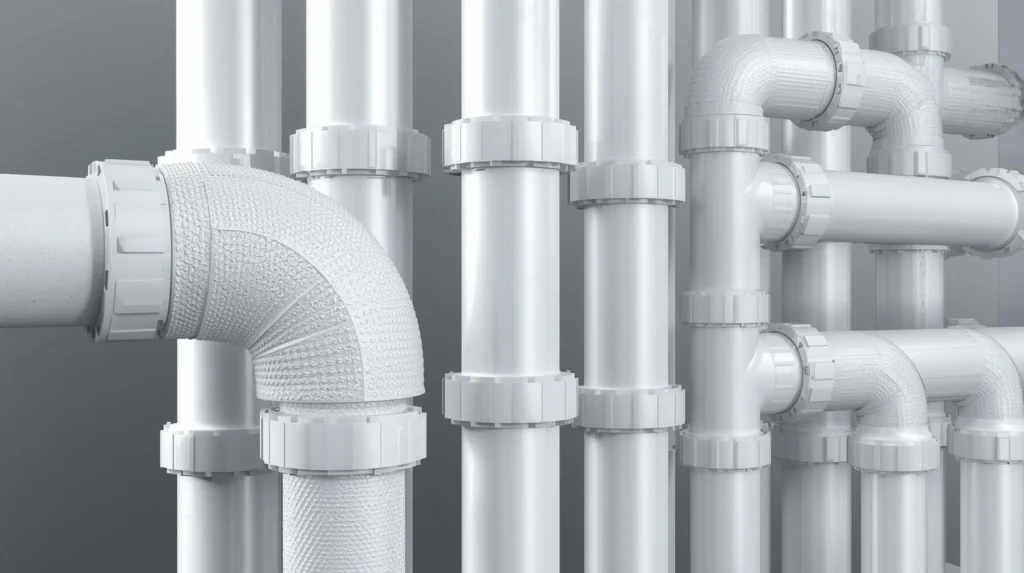

High-Quality Pipes & Fittings – Built to Last

What Makes uPVC Pipes Durable in High-Pressure Systems?

The Durability of uPVC

Durability is essential in high-pressure plumbing systems. uPVC pipes are known for their excellent resistance to stress, corrosion, and cracking, making them ideal for environments where high pressures are sustained over long periods.

Key Durability Factors:

- Impact Resistance: uPVC pipes have superior impact resistance compared to metal pipes, making them less likely to crack or fracture under pressure.

- Thermal Stability: uPVC maintains its integrity across a wide range of temperatures, from freezing conditions to higher heat environments.

- Longevity: uPVC pipes can last for decades in high-pressure systems, reducing the need for replacements and repairs.

By investing in durable uPVC pipes, you ensure that your plumbing system operates smoothly and without interruptions for years to come.

What Installation Considerations Should You Keep in Mind?

Proper Installation is Key

Even the best uPVC pipes won’t perform optimally if not installed correctly. Proper installation techniques can help maintain the integrity of the system and prevent future issues.

Installation Tips:

- Use Proper Fittings: Ensure that all fittings and connections are compatible with the uPVC pipes you’re using. Misaligned or poorly fitted connections can create weak points that are vulnerable under high pressure.

- Follow Manufacturer Guidelines: Always adhere to the installation instructions provided by the manufacturer to avoid voiding any warranties.

- Avoid Sharp Bends: uPVC pipes should not be subjected to sharp bends, as this could weaken the structure and lead to failure under pressure.

Hiring experienced professionals for installation is crucial to ensuring your system functions as intended.

What are the Cost Considerations for High-Pressure uPVC Pipes?

Balancing Cost with Performance

uPVC pipes tend to be more cost-effective than other materials like copper or steel. However, the total cost of installation and maintenance should also include factors like pipe fittings, labor, and long-term performance.

Cost Breakdown:

- Initial Cost: uPVC pipes are affordable compared to metal alternatives, making them an excellent choice for large-scale projects.

- Maintenance: uPVC requires little maintenance, saving costs in the long term.

- Longevity: The durability of uPVC translates to fewer replacements and repairs, adding value over time.

For projects with a tight budget, uPVC pipes are an attractive option for achieving high performance without breaking the bank.

Pro Tips: Expert Insights for Choosing the Right uPVC Pipe

- Consider Environmental Factors: If your plumbing system is exposed to extreme temperatures, UV light, or harsh chemicals, look for uPVC pipes with added UV protection or enhanced chemical resistance.

- Consult with Experts: When in doubt, always consult with a plumbing engineer or technician to determine the optimal pipe size, pressure rating, and installation requirements for your specific project.

- Test and Inspect: Always test the system under controlled pressure to ensure the pipes and fittings can handle the stress before fully activating the system.

Conclusion

Selecting the right uPVC pipes for your high-pressure plumbing system is crucial for ensuring durability, safety, and efficiency. By understanding the importance of pressure ratings, pipe size, installation techniques, and long-term durability, you can make an informed decision that aligns with your needs. Remember, proper installation and regular inspections will help your plumbing system function reliably for years to come.

Call to Action: Ready to upgrade your plumbing system with the right uPVC pipes? Contact a certified plumber today to discuss your high-pressure plumbing needs and get the best solution tailored to your project.

FAQ Section

1. What is the maximum pressure that uPVC pipes can handle?

uPVC pipes typically handle pressures ranging from 6 to 16 Bar, but high-pressure variants can manage pressures exceeding 16 Bar. Always check the manufacturer’s specifications.

2. Can uPVC pipes be used for hot water systems?

Yes, uPVC pipes can handle water temperatures up to 60°C. For higher temperatures, consider CPVC pipes or other heat-resistant materials.

3. Are uPVC pipes prone to cracking under high pressure?

No, uPVC pipes are designed to withstand high pressures. However, improper installation or external impact may cause damage.

4. What factors affect the lifespan of uPVC pipes in high-pressure systems?

Factors include installation quality, water temperature, exposure to UV rays, and chemical content in the water. Proper maintenance extends their lifespan.

5. How do I choose the right size of uPVC pipe for my system?

Choosing the right size depends on your system’s flow rate and pressure requirements. Consult with a plumbing expert to ensure proper sizing for optimal performance.