Have you ever wondered why some pipelines last for decades without a single leak, while others fail prematurely, costing businesses millions? The key often lies in the quality of the welding techniques used in the installation of HDPE (High-Density Polyethylene) pipes. These pipes, known for their durability and corrosion resistance, are integral to modern infrastructure, from water and gas systems to industrial applications. But ensuring they remain leak-free requires a precise fusion welding process. In this blog post, we’ll explore advanced HDPE pipe fusion welding techniques, uncovering how you can achieve leak-free, long-lasting systems.

HDPE Butt-Fusion Welding is one of the most reliable methods for connecting HDPE pipes. The process, though simple in theory, demands expert execution to ensure the integrity of the weld. Unfortunately, many contractors and businesses overlook the intricacies of the fusion process, leading to costly mistakes. In this article, you’ll learn advanced techniques and insights that will not only elevate your welding skills but will also ensure that your systems are leak-free and optimized for longevity.

Key Takeaways:

- Why HDPE Butt-Fusion Welding is crucial for leak-free systems.

- Advanced techniques for achieving strong, reliable fusion joints.

- Best practices for ensuring the highest welding quality in your projects.

What is HDPE Butt-Fusion Welding?

Understanding the Basics of Butt-Fusion Welding

Butt-fusion welding is one of the most effective techniques for joining HDPE pipes. In this method, two pipe ends are heated until they reach a molten state and then pushed together to form a bond. This process creates a homogenous joint, making it nearly as strong as the pipe itself. While simple, the quality of the fusion depends on factors such as temperature, pressure, and time. Even minor deviations in any of these parameters can result in weak or faulty welds.

Why Is It Important?

When performed correctly, butt-fusion welding creates leak-proof joints that are essential for long-term system integrity. The primary advantage is that the fusion process produces a joint that doesn’t just “seal” the pipes together, but chemically bonds them into one seamless entity. This ensures that the welded joint is resistant to environmental pressures, temperatures, and stress — key requirements for industries relying on HDPE pipes, such as construction, water supply, and natural gas distribution.

Advanced Butt-Fusion Welding Techniques for Maximum Strength

Precision Temperature Control: The Heart of the Fusion Process

One of the most critical factors in achieving a strong HDPE weld is controlling the heating temperature. If the pipe ends are heated too much, the material will degrade, weakening the weld. Conversely, insufficient heating results in poor bonding and potential leaks. Advanced fusion machines now feature precise temperature control mechanisms, ensuring that the pipes are heated to the perfect temperature for optimal fusion.

Pro Tip:

To ensure precision, invest in modern fusion machines with digital temperature controls. Regular calibration of the equipment also plays a crucial role in maintaining consistency across your projects.

The Right Pressure: Applying Consistent Force During Fusion

Once the pipe ends reach the ideal molten state, applying the right pressure is essential. Too much pressure can lead to excess material being squeezed out, reducing the strength of the weld. On the other hand, too little pressure results in an insufficient bond, causing weak spots. The correct amount of pressure ensures a smooth and uniform weld, promoting a high-strength joint that can withstand stress.

Expert Insight:

For large-diameter pipes, maintaining consistent pressure is especially important. For these pipes, ensure your welding machine has a robust pressure management system to prevent pressure fluctuations that could compromise the weld.

High-Quality Pipes & Fittings – Built to Last

The Importance of Weld Time: Getting the Duration Just Right

The fusion process requires a specific duration for heating and cooling. Shortening the time may not allow the pipes to melt sufficiently, while extending it too long could cause overheating and material degradation. Monitoring the weld time with precision ensures that the pipes maintain their strength and integrity throughout the process.

For advanced projects, digital time monitors can be invaluable tools. These monitors help adjust welding time based on variables like pipe material type, diameter, and environmental factors, ensuring consistently perfect welds.

Common Mistakes in HDPE Butt-Fusion Welding and How to Avoid Them

Inconsistent Heat Application

A common mistake is uneven heat distribution, often caused by improper machine calibration or lack of monitoring during the fusion process. This can lead to weak spots in the weld, making the system susceptible to leaks.

Actionable Tip:

Perform regular maintenance on your welding machines, and ensure operators are properly trained to identify signs of uneven heat application, such as discoloration or distortion of the pipe ends.

Poor Pipe Alignment

Aligning the two pipe ends is crucial for a strong bond. Misalignment can result in an incomplete or uneven weld, which leads to leakage points.

Expert Insight:

Use pipe alignment tools to ensure that the pipes are perfectly aligned during the fusion process. For larger projects, consider using automatic pipe alignment equipment to increase precision and reduce human error.

Real-World Applications of Advanced HDPE Fusion Welding Techniques

Water Distribution Networks

In water distribution systems, HDPE pipes are often chosen for their resistance to corrosion, flexibility, and longevity. Advanced welding techniques ensure that the joints are leak-free, reducing maintenance costs and extending the life of the infrastructure.

Case Study:

A municipal water authority in the UAE adopted advanced HDPE butt-fusion welding techniques to connect over 100 km of pipelines. The result? A 30% reduction in leak rates and a 50% decrease in system maintenance costs.

Gas Distribution Systems

Gas pipelines need to be airtight, as even the smallest leak can pose a significant safety hazard. HDPE pipe fusion welding offers a reliable and durable solution for these critical systems, ensuring both safety and efficiency.

Mini Case Study:

A natural gas provider in Pakistan switched to advanced butt-fusion welding for their HDPE pipelines. This improved the quality of the welds, which reduced gas leakage by 25% over the first year of operation.

The Future of HDPE Pipe Welding: Trends and Innovations

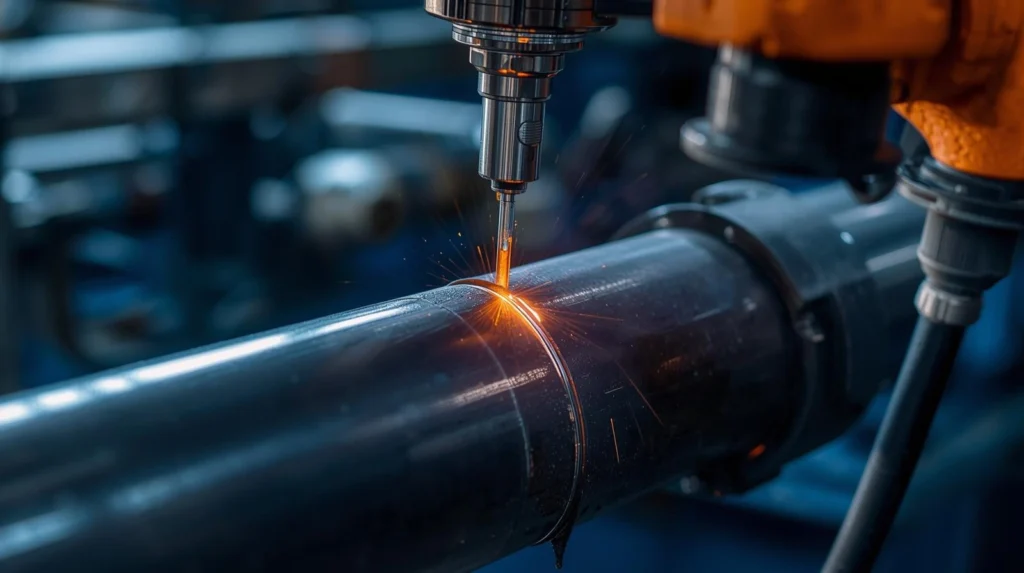

The Rise of Automation in Welding

With technological advancements, more welding processes are becoming automated. Robotic systems are now being used to ensure precise heat, pressure, and timing, making fusion welding even more reliable. These systems not only improve efficiency but also minimize human errors, ensuring the creation of high-quality joints every time.

The Role of Smart Technology in Welding

Smart sensors embedded in HDPE welding machines are now able to monitor conditions in real-time, adjusting parameters like pressure, temperature, and time automatically for optimal results. This technology promises to revolutionize the industry by providing real-time feedback and ensuring that every weld meets the highest standards.

Conclusion

Achieving leak-free systems with HDPE pipes requires more than just the right materials — it takes precision, attention to detail, and advanced welding techniques. By mastering the art of HDPE butt-fusion welding and avoiding common mistakes, you can ensure that your systems are robust, reliable, and long-lasting. Whether you’re building a water distribution network, a gas pipeline, or another infrastructure project, understanding and applying advanced welding techniques will pay off in the long run.

Call to Action:

Are you ready to implement these advanced welding techniques in your next project? Share your thoughts or contact us for expert advice on optimizing your HDPE welding processes.

FAQ Section

1. What is the difference between HDPE butt-fusion welding and other welding methods?

HDPE butt-fusion welding joins two pipe ends by heating them to a molten state and then pressing them together. Unlike other methods like electrofusion or socket fusion, butt-fusion creates a stronger, more durable bond that is ideal for high-pressure systems.

2. How do I know if my HDPE weld is strong enough?

To assess the strength of your weld, check for uniformity and consistency in the joint. Conduct pressure tests and look for any signs of material degradation, such as cracks or weak spots.

3. Can automated systems improve the quality of HDPE fusion welding?

Yes! Automated systems ensure that the heating, pressure, and welding time are consistently controlled, leading to higher-quality welds and fewer errors during the process.

4. How do I maintain HDPE welding equipment?

Regularly clean your welding machine, calibrate it, and replace worn-out parts. Investing in high-quality machines with automatic calibration features will reduce maintenance needs.

5. Why are advanced welding techniques important for gas pipelines?

Gas pipelines require airtight seals to prevent leaks. Advanced welding techniques ensure that each joint is perfectly fused, reducing the risk of dangerous leaks and ensuring system safety.