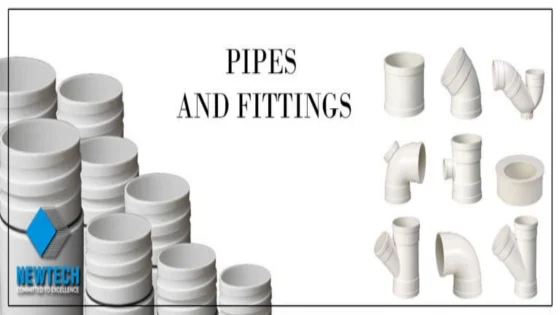

Pipes and Fittings

A Complete Guide about Pipes and Fittings.

A pipe is a tubular section of material that can be used to transfer fluids from one location to another. There are three basic types of pipes: welded, seamless, and threaded pipes. Each type has unique properties and requires different fittings to work properly with other pipes. We’ll break down these types and their corresponding fittings below so you know how to use them correctly in your next plumbing project.

What is Pipe?

A pipe is a plumbing system that carries water. There are many different types of pipes, but the most common type is copper pipe. Pipe in Pakistan is usually either galvanized steel or PVC (polyvinyl chloride).

Pipes in Pakistan are also made of cast iron, brass, lead, plastic, or a combination of materials. PVC pipes have the advantage of being long-lasting. They do not rust or corrode like other metal pipes.

In contrast, galvanized pipes are cheaper than PVC pipes and last as long as they are not exposed to corrosive substances. Galvanized pipes will start corroding if they come into contact with chlorine bleach, salt water, and acidic substances such as vinegar.

Galvanized pipes should be replaced when they start to leak or show signs of corrosion on the inside surface.

Plastic Pipes, UPVC, PVC, and HDPE Pipes

Many different types of pipes are used for various purposes. In Pakistan, the most common types of pipes are CPVC, Plastic Pipes, UPVC, PVC, and HDPE pipes. Each type of pipe has its benefits and drawbacks.

Plastic Pipes:

Plastic pipe is a type of piping made from plastic. It is often used in plumbing and other water-based applications. Plastic pipes are usually white or black and are very easy to cut and join.

There are three main types of plastic pipes: PVC, CPVC, and PEX. PVC is the most common type of plastic pipe. It is strong and durable and can be used for a variety of applications.

CPVC is a type of PVC that is resistant to chemicals and can be used for hot water applications.

CPVC:

PVC Pipe (polyvinyl chloride) has been chlorinated via a free radical chlorination reaction. CPVC Pipe is produced by adding chlorine to PVC in a water slurry or fluidized bed chlorination process.

The chlorination reaction is initiated by ultraviolet light. The chlorinated PVC is compounded with ingredients necessary for the desired properties for further processing.

The chlorine added to PVC gives CPVC higher temperature performance and improved fire and corrosion resistance.

UPVC Pipes:

UPVC pipes are made of unplasticized polyvinyl chloride. This material is strong and resistant to many chemicals, making it ideal for a variety of applications.

UPVC pipes are more expensive than PVC pipes, but they offer some advantages. For example, UPVC pipes are more durable and have a longer lifespan.

They are also less likely to leak and easier to install. Finally, uPVC pipes can be used with other materials such as copper or aluminium because they can be joined together with butt joints or connections.

PVC Pipes:

PVC pipe is a type of plastic piping system that is used for a variety of applications. It is made from a thermoplastic resin and it is very strong and durable. PVC pipe can be used for both hot and cold water applications.

It is also resistant to many chemicals. PVC pipes are often the most economical choice for plumbing because they are more flexible than metal pipes, so they are easier to install in tight spaces.

PVC pipes are available in a range of diameters and wall thicknesses, including standard, extra heavy duty, high pressure, and lightweight types.

HDPE Pipes:

HDPE Pipes and fittings are a type of flexible plastic pipe used for water Supply and gas transfer and are often used to replace ageing concrete or steel main pipelines.

High-density polyethylene pipes for water and gas made from thermoplastic pipes have a high level of permeability and strong molecular bonds which make them suitable for high-pressure pipelines.

Types of CPVC Piping Systems

There are several types of CPVC piping systems available on the market today. Each system has its advantages and disadvantages, so it is important to choose the right one for your needs.

The most common types of CPVC piping systems are Class 1 – This type of system is designed for use in low-pressure applications.

It is made from thin-walled CPVC pipe and fittings that are glued together with solvent cement. Class 2 – This type of system is designed for use in medium-pressure applications.

How to Fix Leaky CPVC Piping

CPVC piping is commonly used in Pakistani households for both hot and cold water lines. If you leak your CPVC piping, there are a few things you can do to fix it. First, try tightening the pipe fitting with a wrench.

If that doesn’t work, you may need to replace the O-ring seal. To do this, simply remove the old O-ring and replace it with a new one.

The Different Types of Ball Valves

There are many different types of ball valves, each with its unique benefits. The most common type of ball valve is the full port ball valve, which has a large opening that allows for maximum flow.

Another popular type is the reduced port ball valve, which has a smaller opening that helps to reduce water pressure. There are also Y-pattern and T-pattern ball valves, which are designed for specific applications.

How to Use Ball Valves in Plumbing Repairs?

One of the most important components in a plumbing system is the pipes and fittings. In Pakistan, many different types of pipes and fittings are used in homes and businesses.

Ball valves are one type of fitting that is often used in plumbing repairs. Here is a quick guide on how to use ball valves when making plumbing repairs.

Pipes fittings

Piping components and fittings constitute indispensable elements within every plumbing infrastructure… They are used to connect pipes, as well as to connect other fixtures such as toilets, sinks, and showers.

There are many different types of pipes and fittings available on the market, so it is important to know which ones you need for your particular project.

Plastic Pipes fittings

Piping components and fittings constitute indispensable elements within every plumbing infrastructure., but they can be confusing to someone who has never worked with them before.

This blog post will explain everything you need to know about pipes and fittings so that you can make sure your next plumbing project goes off without a hitch.

HDPE Pipe fittings

High-density polyethylene (HDPE) pipe fittings are components used to connect HDPE pipes in piping systems. When you need cost-effective, durable, high-performance connections, you need HDPE pipe fittings.

However, figuring out what type of fitting you need can be confusing. Here’s a quick guide to HDPE pipe fittings in Pakistan.

Conclusion Of Pipes and Fittings

Piping components and fittings constitute indispensable elements within every plumbing infrastructure., and they come in a variety of materials, sizes, and shapes. In Pakistan, the most common type of pipe is PVC, but there are also metal, clay, and concrete pipes.

The size of the pipe you need depends on the job you’re doing. Fittings are used to connect two pieces of pipe or to connect pipe to a fixture, such as a faucet or a toilet.

Thanks for Reading!

In the realm of plumbing, the importance of pipes and fittings cannot be overstated. From carrying water to connecting fixtures, these components form the backbone of any plumbing system. Understanding the different types of pipes, such as PVC, CPVC, and HDPE, along with their corresponding fittings, is essential for ensuring a successful plumbing project. Whether you’re repairing a leaky CPVC line or selecting the right ball valve for a specific application, having the knowledge of pipes and fittings at your disposal is invaluable. With a wide array of materials, sizes, and shapes available, navigating the world of plumbing components can be daunting, but armed with the right information, you can tackle any project with confidence.