UPVC pressure pipes and fittings are vital for modern infrastructure, especially in water supply systems. Engineered for durability and reliability, they resist corrosion, withstand high pressures, and offer smooth water flow. Adhering to international standards, UPVC components are available in diverse configurations, ensuring compatibility with various project needs. Their environmental sustainability, ease of installation, and versatile applications make them essential in shaping resilient infrastructure.

Introduction to UPVC Pressure Pipes and Fittings

UPVC (Unplasticized Polyvinyl Chloride) pressure pipes and fittings are integral components of modern infrastructure, particularly in water supply systems. Offering exceptional durability, reliability, and versatility, UPVC pipes and fittings play a crucial role in ensuring the efficient conveyance of water in residential, commercial, and industrial settings. This article explores the significance of UPVC pressure pipes and fittings, their various types, jointing systems, advantages, applications, and their indispensable contribution to contemporary infrastructure development.

Overview of UPVC Pipes and Fittings

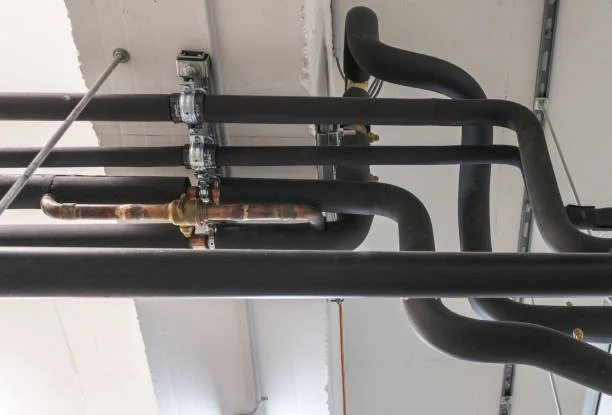

UPVC pipes and fittings are engineered from rigid PVC material, making them highly resistant to chemical corrosion and deterioration over time. These components are designed to withstand high pressure and temperature conditions, ensuring long-term performance and reliability in water distribution networks. UPVC fittings encompass a diverse range of configurations, including couplings, elbows, tees, reducers, and end caps, providing versatility and adaptability to various plumbing requirements.

Importance in Water Supply Systems

In water supply systems, UPVC pressure pipes and fittings serve as the lifeline for delivering clean and potable water to communities, households, and industries. Their robust construction and corrosion-resistant properties make them ideal for underground installations, where they can withstand soil movement, external stresses, and harsh environmental conditions. Moreover, UPVC pipes offer smooth internal surfaces, minimizing friction losses and optimizing water flow efficiency throughout the distribution network.

Types of UPVC Pipes and Fittings

The market offers a comprehensive range of UPVC pipes and fittings to cater to diverse applications and pressure requirements. From standard fittings to specialized components for specific industrial applications, there is a wide selection available to meet varying project needs. UPVC pipes are manufactured in various sizes and pressure classes, ensuring compatibility with different system specifications and hydraulic conditions.

Conformity to International Standards

UPVC pipes and fittings adhere to stringent international standards such as ISO, ensuring uniformity, quality, and performance across global markets. Compliance with these standards guarantees that UPVC products meet the requirements for durability, safety, and reliability in water supply systems and other infrastructure projects.

Jointing Systems for UPVC Pipes

Two primary jointing systems are commonly used for UPVC pipes: the solvent cement jointing system and the Z joint/rubber ring jointing system. The solvent cement jointing system involves the application of a specialized solvent cement to bond the pipe and fitting together permanently. Conversely, the Z joint/rubber ring jointing system utilizes a rubber ring inserted into a grooved socket to create a watertight seal upon assembly.

Procedure for Installation

In the solvent cement jointing system, the procedure involves cleaning the mating surfaces of the pipe and fitting, applying solvent cement evenly to both surfaces and quickly joining them together before the cement sets. Conversely, the Z joint/rubber ring jointing system requires careful preparation of the socket and spigot, ensuring that the rubber ring is properly seated before assembly. Both jointing systems necessitate meticulous attention to detail and adherence to recommended installation practices to ensure leak-free connections.

Advantages of UPVC Pressure Pipes and Fittings

UPVC pressure pipes and fittings offer numerous advantages over traditional materials such as metal or concrete. These include:

– Corrosion resistance: UPVC is inherently resistant to corrosion, ensuring long-term performance and durability in aggressive soil and water conditions.

– Flexibility and ease of installation:

UPVC pipes are lightweight and flexible, allowing for easy handling and installation in confined spaces or challenging terrain.

– Thermal insulation properties: UPVC exhibits excellent thermal insulation properties, reducing heat loss or gain in water distribution systems and enhancing energy efficiency.

– Environmental benefits:

UPVC is a recyclable material that does not contain harmful chemicals, making it an environmentally sustainable choice for infrastructure projects.

Applications of UPVC Pressure Pipes and Fittings

UPVC pressure pipes and fittings find extensive applications across various sectors and industries, including:

– Water supply systems:

UPVC pipes are widely used in municipal, residential, and industrial water distribution networks due to their reliability, longevity, and cost-effectiveness.

– Industrial applications:

UPVC pipes play a vital role in industrial processes such as chemical processing, wastewater management, and manufacturing, where corrosion resistance and durability are paramount.

– Agricultural irrigation systems:

UPVC pipes are utilized in agricultural irrigation systems to transport water efficiently to fields, orchards, and crops, promoting sustainable agriculture and maximizing crop yields.

UPVC pressure pipes and fittings are vital components of modern infrastructure, ensuring reliable water conveyance in various applications. For premium-grade UPVC pipes and fittings engineered for durability and compatibility, visit our website for a comprehensive range tailored to meet diverse project needs.

As the demand for sustainable infrastructure grows, UPVC pressure pipes and fittings continue to play a pivotal role in shaping resilient water supply systems worldwide. Explore our range of UPVC components engineered for durability, reliability, and environmental sustainability, available at your convenience on our website.

Conclusion Of UPVC Pressure Pipes and Fittings

In conclusion, UPVC pressure pipes and fittings are indispensable components of modern infrastructure, essential for the reliable and efficient conveyance of water in various applications. Their robust construction, corrosion resistance, and ease of installation make them the preferred choice for water supply systems, industrial processes, and agricultural irrigation networks worldwide. As the demand for sustainable and resilient infrastructure continues to grow, the importance of UPVC pipes and fittings in modern infrastructure development cannot be overstated. Their versatility, reliability, and environmental sustainability make them invaluable assets in shaping the future of infrastructure for generations to come.

Frequently Asked Questions (FAQs) About UPVC Pressure Pipes

1. What are UPVC pressure pipes and fittings?

– UPVC (Unplasticized Polyvinyl Chloride) pressure pipes and fittings are rigid components used in water supply systems for conveying pressurized water. They are highly durable and resistant to corrosion, making them ideal for various applications.

2. What types of UPVC pipes and fittings are available?

– UPVC pipes and fittings come in a range of configurations, including couplings, elbows, tees, reducers, and end caps. They are available in various sizes to accommodate different pressure classes and conform to international standards.

3. How are UPVC pipes and fittings installed?

– UPVC pipes can be joined using solvent cement or the Z joint/rubber ring jointing system. The installation process involves cleaning the mating surfaces, applying solvent cement or inserting a rubber ring, and securely joining the components.

4. What are the advantages of UPVC pressure pipes and fittings?

– UPVC pressure pipes and fittings offer corrosion resistance, flexibility, ease of installation, thermal insulation properties, and environmental benefits. They are lightweight, durable, and sustainable, making them suitable for a wide range of applications.

5. Where are UPVC pressure pipes and fittings used?

– UPVC pressure pipes and fittings are commonly used in water supply systems, industrial applications, and agricultural irrigation systems. They provide reliable and efficient water conveyance, contributing to the development of modern infrastructure.