Application Of Electrical Conduit Pipe

Introduction

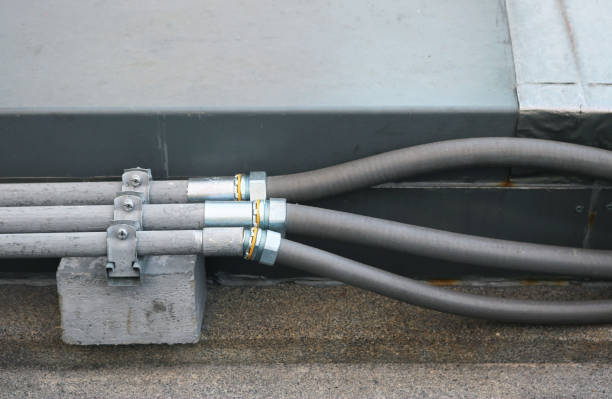

Electrical conduit pipes play a crucial role in ensuring the safe and efficient distribution of electrical power and communication cables within diverse infrastructures. These conduit systems serve as protective channels, encasing wiring to shield it from physical damage, moisture, and other environmental factors. The electrical conduit pipes is fundamental in organizing and safeguarding wiring installations, contributing to the overall reliability and longevity of electrical systems.

These conduit pipes are constructed from various materials such as PVC (Polyvinyl Chloride), galvanized steel, and rigid metal conduits, each chosen based on specific project requirements, environmental considerations, and the type of wiring being utilized. The versatility of conduit pipes extends to different types, including rigid metal conduit (RMC), electrical metallic tubing (EMT), flexible conduits, and PVC conduits, allowing for tailored solutions in various applications.

Whether used in residential, commercial, industrial, or outdoor settings, electrical conduit pipes provide mechanical protection, preventing physical harm to wires, and ensuring compliance with safety standards. They are integral in underground wiring installations, safeguarding cables from moisture and soil conditions. Additionally, conduit pipes find application in data centers, communication facilities, and even renewable energy projects, showcasing their adaptability in diverse technological landscapes.

This introduction sets the stage for exploring the multifaceted application areas of electrical conduit pipes, emphasizing their significance in creating secure and organized electrical infrastructures across a spectrum of industries and settings.

Application Areas of Electrical Conduit Pipes:

- Residential Wiring:

- Electrical conduit pipes are commonly used in residential buildings for the safe and organized installation of wiring, protecting cables from physical damage.

- Commercial Buildings:

- Conduit pipes find extensive use in commercial structures, providing a secure pathway for electrical wiring in offices, retail spaces, and other commercial establishments.

- Industrial Facilities:

- In industrial settings, conduit pipes are employed to safeguard electrical wiring from harsh environmental conditions, ensuring reliable power distribution in factories and manufacturing plants.

- Outdoor Installations:

- Conduit pipes, especially those designed for outdoor use, are applied in installations such as street lighting, landscape lighting, and outdoor electrical infrastructure.

- Underground Wiring:

- Conduit pipes are essential for underground wiring installations, protecting cables from moisture, soil conditions, and external elements.

- Data and Communication Centers:

- In data centres and communication facilities, conduit pipes provide a structured and secure pathway for data cables and wiring, ensuring efficient and organized installations.

- Healthcare Facilities:

- Hospitals and medical facilities utilize conduit pipes to manage wiring for critical equipment, ensuring a safe and reliable electrical infrastructure in healthcare settings.

- Educational Institutions:

- Conduit pipes are used in schools, colleges, and universities to organize and protect electrical wiring in classrooms, laboratories, and administrative areas.

- Transportation Infrastructure:

- Conduit pipes are applied in transportation projects, such as tunnels, bridges, and transit systems, to protect electrical wiring for lighting, signalling, and communication systems.

- Utilities and Power Plants:

- Electrical conduit pipes play a vital role in utility installations and power plants, providing a secure conduit system for the distribution of power and control cables.

- Public Spaces and Venues:

- Conduit pipes are utilized in public spaces, stadiums, and entertainment venues to support electrical installations for lighting, sound systems, and other infrastructure.

- Renewable Energy Projects:

- Conduit pipes are integral in renewable energy projects, facilitating the organized installation of wiring for solar panels, wind turbines, and other sustainable energy systems.

- Rescue and Emergency Services:

- Emergency services and rescue operations may use conduit pipes to organize and protect wiring in command centers, emergency response vehicles, and critical communication hubs.

- Government Buildings:

- Conduit pipes are applied in government facilities to ensure the safety and organization of electrical wiring in offices, meeting rooms, and administrative areas.

Understanding the diverse application areas of electrical conduit pipes highlights their versatility and importance in creating safe and organized electrical infrastructures across various sectors.

Essential Characteristics:

- Material Durability:

- Electrical conduit pipes typically boast robust construction from materials such as PVC (Polyvinyl Chloride), galvanized steel, or rigid metal conduits, ensuring prolonged protection for electrical wiring.

- Corrosion Resistance:

- Conduit pipes, especially those crafted from materials like PVC or galvanized steel, demonstrate resilience against corrosion, enhancing their endurance across diverse environments.

- Mechanical Protection:

- A primary function of conduit pipes is to furnish mechanical protection for electrical wires, shielding them from physical damage, impact, and environmental factors.

- Flexibility and Bendability:

- Specific conduit pipes, notably flexible conduits, provide flexibility and bendability, making them apt for installations in confined or curved spaces.

- Ease of Installation:

- Conduit pipes are engineered for straightforward installation, often featuring connectors and fittings that streamline the assembly process, ensuring both simplicity and security.

- Non-Conductive Properties:

- PVC conduit pipes exhibit non-conductive attributes, adding an extra layer of safety by impeding the conduction of electricity and mitigating the risk of electrical hazards.

- UV Resistance:

- Certain conduit materials, such as UV-resistant PVC, are tailored to endure exposure to ultraviolet (UV) rays, guaranteeing durability in outdoor settings.

- Fire Resistance:

- Certain conduit materials possess intrinsic fire-resistant properties, contributing to the safety of electrical systems by minimizing the risk of fire propagation.

- Chemical Resistance:

- Conduit pipes crafted from specific materials showcase resistance to a variety of chemicals, rendering them suitable for installations in environments with exposure to corrosive substances.

- Smooth Interior Surface:

- Conduit pipes often feature a sleek interior surface, facilitating the effortless pulling and feeding of electrical wires, minimizing friction, and reducing the likelihood of wire damage.

- Compliance with Standards:

- Quality conduit pipes adhere to industry standards and regulations, ensuring alignment with safety and performance requirements for electrical installations.

- Varied Sizes and Types:

- Conduit pipes are available in diverse sizes and types, encompassing rigid metal conduit (RMC), electrical metallic tubing (EMT), and flexible conduits, offering choices for different applications and wiring needs.

- Weather Resistance:

- Outdoor conduit pipes are crafted to withstand a spectrum of weather conditions, safeguarding the integrity of electrical systems in both indoor and outdoor environments.

- Ease of Maintenance:

- Conduit systems are generally low-maintenance, demanding minimal attention once correctly installed, contributing to the overall efficiency of electrical infrastructure.

Salient Key Features of Electrical Conduit Pipes:

-

-

- Robust Material Construction:

- Electrical conduit pipes are crafted from sturdy materials, such as PVC, galvanized steel, or rigid metal conduits, ensuring resilience and durability in diverse environments.

- Corrosion Resistance:

- Exhibiting resistance to corrosion, conduit pipes maintain their structural integrity over time, making them suitable for installations in varied atmospheric conditions.

- Mechanical Protection:

- A primary function of conduit pipes is to provide reliable mechanical protection for electrical wiring, shielding against physical impact, vibrations, and external elements.

- Flexibility and Bendability:

- Certain conduit pipes offer flexibility and bendability, allowing for easy installation in confined or curved spaces without compromising the integrity of the electrical system.

- Easy Installation:

- Engineered for user-friendly installation, conduit pipes often feature connectors and fittings that streamline the assembly process, ensuring simplicity and efficiency.

- Non-Conductive Properties:

- PVC conduit pipes, in particular, possess non-conductive properties, enhancing safety by preventing the conduction of electricity and reducing the risk of electrical hazards.

- UV Resistance:

- UV-resistant conduit materials, like certain types of PVC, are designed to withstand exposure to ultraviolet rays, ensuring longevity in outdoor applications.

- Fire Resistance:

- Some conduit materials have inherent fire-resistant properties, contributing to overall safety by minimizing the risk of fire propagation in the event of electrical faults.

- Chemical Resistance:

- Conduit pipes made from specific materials showcase resistance to various chemicals, making them suitable for installations in environments with exposure to corrosive substances.

- Smooth Interior Surface:

- Featuring a smooth interior surface, conduit pipes facilitate easy pulling and feeding of electrical wires, reducing friction and the potential for wire damage during installation.

- Compliance with Standards:

- High-quality conduit pipes adhere to industry standards and regulations, ensuring they meet safety and performance requirements for electrical installations.

- Varied Sizes and Types:

- Available in diverse sizes and types, including rigid metal conduit (RMC), electrical metallic tubing (EMT), and flexible conduits, providing options for different applications and wiring needs.

- Weather Resistance:

- Outdoor conduit pipes are designed to withstand various weather conditions, ensuring the integrity of electrical systems in both indoor and outdoor environments.

- Low Maintenance Requirements:

- Conduit systems are generally low-maintenance, requiring minimal attention once correctly installed, contributing to the overall efficiency of electrical infrastructure.

- Robust Material Construction:

-

Frequently Asked Questions

Q1: How are electrical conduit pipes used in residential settings? A1: Electrical conduit pipes are commonly employed in homes to protect and organize wiring, ensuring a secure pathway for electrical power. They contribute to safety and longevity in residential electrical systems.

Q2: Are HDPE pipes suitable for underground electrical conduit applications? A2: Yes, HDPE pipes are often used for underground electrical conduit applications due to their durability, resistance to moisture, and protective qualities, making them ideal for safeguarding cables in below-ground installations.

Q3: In what industrial applications are electrical conduit pipes utilized? A3: Industrial facilities extensively use electrical conduit pipes to protect wiring from harsh environments, mechanical damage, and external factors. They are integral in ensuring the reliability of electrical infrastructure in manufacturing plants and factories.

Q4: How do HDPE pipes contribute to the longevity of conduit systems? A4: HDPE pipes, known for their durability and resistance to corrosion, enhance the longevity of conduit systems. They protect wiring from environmental elements, ensuring a prolonged and reliable service life.

Q5: Can electrical conduit pipes be used for data and communication wiring? A5: Yes, electrical conduit pipes are commonly used for organizing and protecting data and communication wiring. They offer a secure channel for network cables, contributing to efficient and organized installations.

Q6: What sets HDPE pipes apart in outdoor conduit applications? A6: HDPE pipes excel in outdoor conduit applications due to their weather-resistant properties. They withstand environmental conditions, making them suitable for outdoor installations where protection against the elements is crucial.

Q7: Are electrical conduit pipes suitable for industrial control and power plants? A7: Yes, electrical conduit pipes are vital in industrial control systems and power plants. They provide a secure conduit system for power and control cables, ensuring reliability and safety in critical infrastructure.

Q8: How can HDPE pipes be utilized in irrigation systems? A8: HDPE pipes are commonly used in irrigation systems due to their resistance to chemicals and durability. They provide a reliable conduit for water supply in agricultural and irrigation applications.

Q9: Can electrical conduit pipes be installed above ground? A9: Yes, electrical conduit pipes can be installed both above and below ground. Above-ground installations contribute to the organization and protection of wiring in various construction scenarios.

Q10: What considerations are important in selecting HDPE pipes for conduit applications? A10: When selecting HDPE pipes for conduit applications, factors such as diameter, pressure rating, and material quality are crucial. HDPE pipes should meet project specifications and industry standards to ensure optimal performance.