Plastic Pipe: Every Thing you need to know

Plastic pipe is the best pipe for your home. Plastic pipes don’t rust and discolor the way metal pipes do, so they won’t mar the look of your home’s interior or exterior appearance in any way.

They also never expand or contract due to changes in temperature, and they are impervious to impact damage, which means you can throw them around without worry! Plastic has never been so good!

What is Plastic Pipe?

Plastic pipe is a type of piping made from plastic. It is often used in plumbing and other water-based applications. Plastic pipes are usually white or black and are very easy to cut and join.

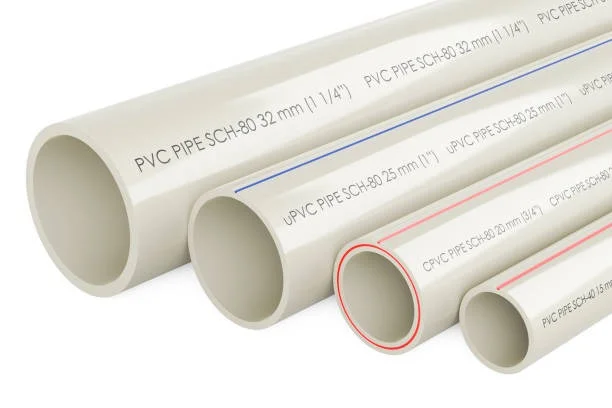

There are three main types of plastic pipes: PVC, CPVC, and PEX. PVC is the most common type of plastic pipe. It is strong and durable and can be used for a variety of applications.

CPVC is a type of PVC that is resistant to chemicals and can be used for hot water applications.

Types of Plastic Pipes

There are three basic types of plastic pipes:

- Solid wall pipe

- Structured wall pipe

- Barrier pipe

Solid Wall Pipe

Pipes are made of one, solid layer of thermoplastic material for use in pipelines.

Structured wall pipe

Structured-wall pipes and fittings are products that have been designed to use less material while meeting all of the necessary requirements.

Structured Wall Pipes are tailor-made solutions of piping systems, for a variety of applications and in most cases developed in cooperation with users.

Barrier Pipe

The pipe incorporates a flexible metallic layer between two solid layers. Barrier pipes are typically used to protect the contents of the pipe from chemical contamination while in contact with soil.

Most plastic pipe systems are made from thermoplastics such as PVC or ABS. Plastic pipes can also be produced by injection molding and cutting, or compression molding.

Standards

Plastic pipes are made to different standards than metal pipes. Plastic pipe fittings are also made to different standards. Plastic pipes for water lines have been tested and certified by NSF International. Several plastic pipe manufacturers have been certified by NSF International.

Plastic pipes may not be as expensive as metal pipes, but they can save you money in the long run. The plastic material is easier to install, less expensive to maintain, and will never corrode or rust. Plastic pipe fittings are also less expensive because of their durable construction.

Materials used

- ABS (Acrylonitrile Butadiene Styrene)

- CPVC (Chlorinated Polyvinyl Chloride)

- HDPE (High-Density Polyethylene))

- PB-1 (polybutylene)

- PE (polyethylene) of various densities, also abbreviated to LDPE, MDPE, and HDPE (low, medium, and high-density polyethylene: the medium-density version is at times referred to as “black alkaline” in the UK)

- PE-RT (polyethylene of Raised Temperature (RT))

- PEX (cross-linked polyethylene)

- PP (polypropylene)

- PVDF (Polyvinylidene Difluoride)

- UPVC (Unplasticized Polyvinyl Chloride)

Material characteristics

ABS. (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is used for the conveyance of potable water, slurries, and chemicals. Most commonly used for DWV (drain-waste-vent) applications. It has a wide temperature range, from -40 °C to +60 °C.

ABS is a thermoplastic material and was originally developed in the early 1950s for use in oil fields and the chemical industry. The variability of the material and its relative cost-effectiveness have made it a popular engineering plastic.

It can be tailored to suit many different needs by altering the proportions of the individual polymers within it depending on what you need it for – usually high impact strength or rigidity are required so these plastics are particularly suited to mechanical engineering uses.

CPVC

CPVC is resistant to many acids, bases, salts, paraffinic hydrocarbons, halogens, and alcohols. It is not resistant to solvents, aromatics, and some chlorinated hydrocarbons.

It can carry higher temperature liquids than uPVC with a max operating temperature reaching 200 °F (93.3 °C). Due to its greater temperature threshold and chemical resistance, CPVC remains one of the most recommended material choices for residential, commercial, and industrial water transport installations.

HDPE

HDPE (High-Density Polyethylene) – HDPE pipe is strong, flexible, and lightweight. This type of pipe has a zero leak rate when fused together thanks to its design.

PB-1 (polybutylene)

The polyethylene derivative polybutylene is used in pressure piping systems for hot and cold potable water, pre-insulated district heating networks, and surface heating and cooling systems.

The material’s key qualities include its weldability, ease of use, durability under high pressures, and no corrosion or calcification when exposed to harsh conditions.

Polybutylene has little market share throughout North America. In European countries such as the UK, France, Poland, and Spain it retains a substantial market presence while in places like China, it maintains only a small percentage of the market share.

PE (polyethylene)

Polyethylene (PE) piping has been in use for many years for the conveyance of potable and wastewater, hazardous waste, and compressed gases.

Two variants are high-density polyethylene (HDPE pipe), which can withstand higher temperatures than traditional polyethylene, and cross-linked polyethylene (PEX), which is even more heat resistant. PE piping was first introduced commercially in the early 1950s.

Lightweight, flexible, and easy to weld, it also comes with an attractive smooth interior finish ensuring good flow characteristics. Continuous development of this versatile material has led to a rapid increase in its usage by major utilities around the world.

PE-RT

Polyethylene of Raised Temperature (RT) or PE-RT expands the traditional properties of polyethylene. Thermally enhanced polyethylene is thus made possible through special molecular design and manufacturing process control, an ability to withstand both high and low temperatures without cracking.

This allows it to be used for a wide variety of hot and cold water pipe applications.

PP (Polypropylene)

PP is a thermoplastic polymer made from polypropylene. It was first invented in the 1950s and has been used for pipes since the 1970s. Due to its high impact resistance combined with good stiffness and high chemical resistance, this material can be found in sewer systems across the world.

With an ability to resist temperatures of up to 140 degrees Fahrenheit or 60 degrees Celsius, it can also withstand short-term exposure of 194 degrees Fahrenheit or 90 degrees Celsius—making it a sought-after option for residential plumbing systems.

UPVC (Unplasticized Polyvinyl Chloride)

Polyvinyl Chloride is an unplasticized substance obtained through coal, salt, and oil. This material has been in use since the 30s when it was created. Beginning in the 50s, this material was used to replace corroded metal pipes because of its high durability.

Polyvinyl Chloride is certified safe for drinking water according to NSF Standard 61 and has been widely used for water distribution lines throughout North America and other parts of the world. This material can also be found within household plumbing systems including sewer pipes.

Components of plastic pressure pipe systems

Pipe, fitting, valve, and accessory systems comprise plastic piping for pressure purposes. They can vary between pipe diameters ranging from 12 to 400 mm (0.472 to 15.748 in) and 3⁄8 – 16 in (9.53 – 406.40 mm).

This product comes in 10 m or 100 meters per coil with lengths of either 2 m or 4 meters which come with standard butt weld end joints which may require the use of a heat sealer or welding procedure during installation; pipes are typically extruded out of a gauge sheet consisting mainly out of low-density polyethylene or high-density polyethylene and it is common usage that such pipes do provide potential additional length savings when laying installed piping systems where they’re inserted after existing piping has been laid at junctions between branching points along an axis within mechanical rooms or above heads giving it lower resistance under pressures caused by cocks ̍or load cells.

Conclusion: Plastic Pipes Every Thing you need to know

In conclusion, plastic pipes are the best pipes for your home due to their many benefits. They are durable, easy to install, and require less maintenance than other types of pipes.

Plastic pipes also have a lower risk of leaking and bursting, which can save you money in the long run. With all of these advantages, it’s no wonder that the plastic pipes market is growing rapidly.

Incorporating plastic pipes into your home’s plumbing system offers numerous advantages, from durability and ease of installation to resistance against corrosion and chemical degradation. With a wide range of materials available, such as PVC, CPVC, PEX, and HDPE, plastic pipes cater to various needs and applications, ensuring reliable water supply and wastewater management. Moreover, plastic pipes are lightweight, cost-effective, and environmentally friendly, making them an ideal choice for homeowners seeking efficient and sustainable plumbing solutions. Whether for residential, commercial, or industrial use, plastic pipes continue to revolutionize the piping industry, providing reliable performance and long-term durability for countless applications.