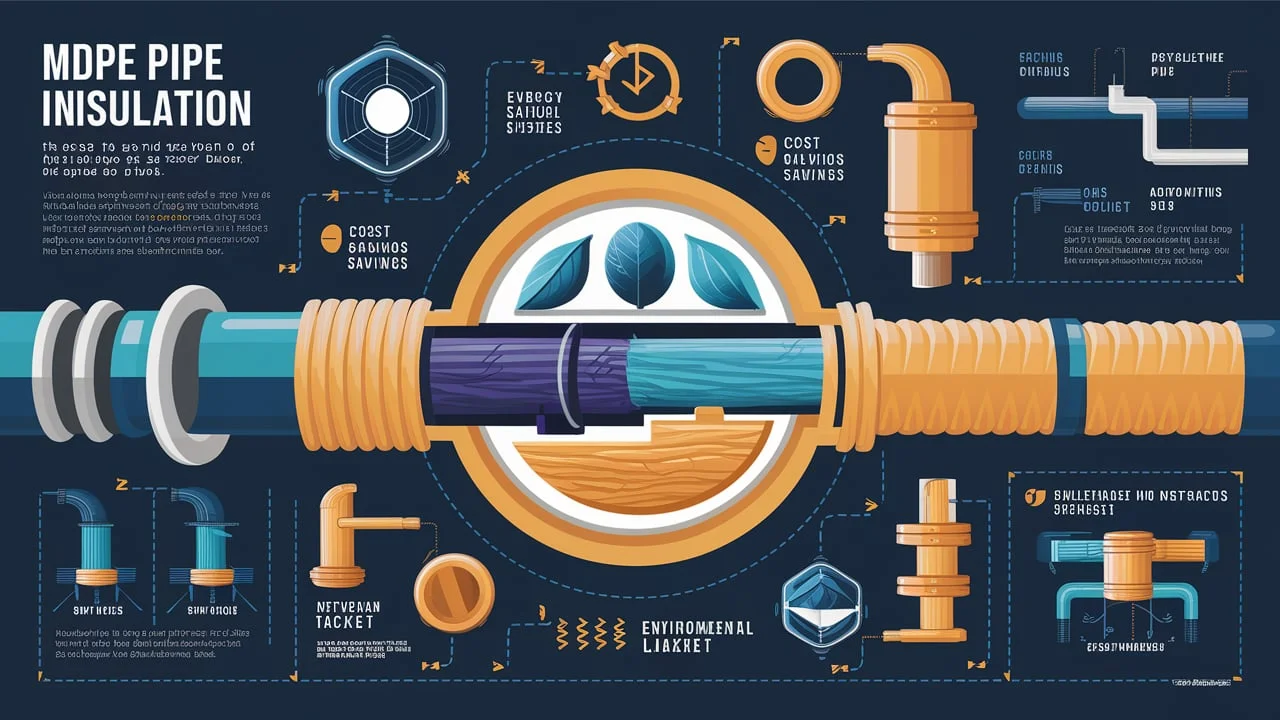

MDPE pipe insulation is an essential component for enhancing the efficiency and longevity of piping systems. Made from medium-density polyethylene, this insulation material provides exceptional thermal protection, reduces energy consumption, and extends the lifespan of pipes. It prevents issues such as heat loss, freezing, and pipe bursts, making it a cost-effective solution for both residential and industrial applications. This article explores the benefits and techniques of MDPE pipe insulation, compares it with other materials, and offers practical insights into its applications, maintenance, and future advancements.

MDPE Pipe Insulation: Benefits and Techniques

Introduction of MDPE Pipe Insulation

In modern construction and maintenance, effective pipe insulation is crucial for optimizing system efficiency and longevity. MDPE pipe insulation, crafted from medium-density polyethylene, offers a sophisticated solution to various piping challenges. This article explores the benefits and techniques associated with MDPE pipe insulation, providing a comprehensive guide to enhancing your piping systems.

Understanding MDPE Pipe Insulation

What is MDPE Pipe Insulation?

MDPE pipe insulation is a protective covering made from medium-density polyethylene (MDPE) designed to encase pipes and safeguard them from temperature fluctuations, physical damage, and environmental stressors. This material is known for its robustness, flexibility, and resistance to various external factors, making it an excellent choice for insulating pipes in diverse settings.

Overview of MDPE (Medium-Density Polyethylene)

Medium-density polyethylene (MDPE) is a type of polyethylene characterized by its moderate density and strength, falling between low-density polyethylene (LDPE) and high-density polyethylene (HDPE). It combines the flexibility of LDPE with the strength of HDPE, resulting in a versatile material that excels in various applications, including pipe insulation. Its molecular structure provides a balance of durability and pliability, making it ideal for maintaining consistent insulation performance.

Why MDPE is Preferred for Insulation

MDPE is favored for pipe insulation due to its excellent thermal properties, durability, and ease of installation. It maintains its insulating effectiveness over a wide temperature range, resists moisture absorption, and withstands environmental wear and tear. Additionally, MDPE’s flexibility allows for easy application around pipes of different sizes and shapes, ensuring comprehensive coverage and protection.

Key Benefits of MDPE Pipe Insulation

Enhanced Thermal Efficiency

MDPE pipe insulation significantly improves thermal efficiency by minimizing heat loss and maintaining the desired temperature of the fluid within the pipes. This ensures that the energy used to heat or cool the fluid is not wasted, leading to more efficient and cost-effective operations.

Reduction in Heat Loss and Energy Consumption

By effectively reducing heat loss, MDPE insulation lowers the energy required to maintain optimal temperatures. This reduction in energy consumption not only helps in reducing utility bills but also contributes to a more sustainable and eco-friendly operation.

Prevention of Freezing and Pipe Bursts

MDPE insulation provides a protective barrier against extreme temperatures, preventing the freezing of fluids within the pipes. This is crucial in preventing pipe bursts during cold weather, which can lead to significant damage and costly repairs.

Extended Pipe Lifespan

The durability of MDPE insulation extends the lifespan of pipes by shielding them from environmental factors and mechanical damage. This protective layer helps in reducing wear and tear, corrosion, and other forms of deterioration, ensuring that pipes remain functional for a longer period.

Cost-Effective Solution for Insulation

Given its durability and effectiveness, MDPE pipe insulation offers a cost-effective solution compared to other materials. Its long-lasting nature and minimal maintenance requirements translate into reduced overall costs and better value for investment.

Techniques for Implementing MDPE Pipe Insulation

Choosing the Right Insulation Thickness

Selecting the appropriate thickness of MDPE insulation is essential for achieving optimal performance. The thickness depends on factors such as the pipe’s size, the ambient temperature, and the required thermal resistance. Proper thickness ensures that the insulation performs effectively in maintaining temperature and preventing energy loss.

Installation Methods for MDPE Insulation

MDPE pipe insulation can be installed using various methods, including pre-slit foam tubes and self-adhesive wraps. Each method requires careful handling to ensure a snug fit around the pipes and effective sealing. Proper installation is crucial for maximizing the insulation’s benefits and preventing gaps that could compromise performance.

Step-by-Step Guide to Proper Installation

- Preparation: Clean the pipe surface to remove any debris or contaminants.

- Measurement: Measure the pipe length and cut the MDPE insulation to the appropriate size.

- Application: Position the insulation around the pipe, ensuring it covers the entire surface.

- Sealing: Secure the insulation with adhesive tape or other fastening methods to prevent movement and gaps.

- Inspection: Check for proper fit and seal, and make any necessary adjustments.

Sealing and Jointing Techniques for MDPE Pipes

Proper sealing and jointing are vital for maintaining the integrity of the insulation. Use high-quality adhesive tapes or sealants designed for MDPE to secure joints and overlaps. Ensuring a tight seal prevents moisture ingress and maintains the insulation’s effectiveness.

Comparison with Other Insulation Materials

MDPE vs. Polyethylene Foam Insulation

While both MDPE and polyethylene foam insulation offer effective thermal protection, MDPE provides greater durability and resistance to environmental factors. Polyethylene foam may be more flexible but can be less resilient under harsh conditions.

MDPE vs. Rubber Insulation

Rubber insulation is known for its excellent thermal performance and flexibility, but MDPE offers superior strength and resistance to physical damage. Rubber may be preferred in specific applications requiring higher flexibility.

MDPE vs. Fiberglass Insulation

Fiberglass insulation provides excellent thermal resistance but can be more challenging to handle and install compared to MDPE. MDPE’s flexibility and ease of installation make it a more user-friendly option for many piping systems.

Applications of MDPE Pipe Insulation

Residential Use

In residential settings, MDPE pipe insulation is commonly used for domestic water pipes, heating systems, and cooling systems. Its ability to prevent heat loss and protect against freezing makes it ideal for maintaining comfortable temperatures and preventing costly damage.

Commercial and Industrial Applications

For commercial and industrial applications, MDPE insulation is employed in larger-scale systems, including HVAC systems, process piping, and chemical transport. Its durability and effectiveness ensure that industrial operations run efficiently and safely.

Specialty Applications: Heating Systems and Cold Storage

MDPE pipe insulation plays a crucial role in heating systems, where it helps in maintaining consistent temperatures and reducing energy costs. In cold storage facilities, it ensures that refrigeration systems operate efficiently by preventing thermal loss.

Maintenance and Troubleshooting

Routine Maintenance Tips

Regular maintenance involves inspecting the insulation for any signs of damage or wear. Ensure that the insulation remains intact and properly sealed, and address any issues promptly to maintain optimal performance.

Common Issues and How to Address Them

Common issues with MDPE pipe insulation include damage from external impacts, deterioration due to UV exposure, and improper installation. Address these issues by repairing or replacing damaged sections and ensuring proper installation techniques.

How to Inspect Insulated Pipes

Inspect insulated pipes by visually examining the insulation for any gaps, tears, or signs of wear. Ensure that the insulation is securely fastened and covers the entire pipe surface without any noticeable gaps.

Environmental Impact and Sustainability

Eco-Friendly Aspects of MDPE Insulation

MDPE insulation is designed with environmental sustainability in mind. It is often manufactured from recyclable materials and contributes to energy efficiency, reducing the overall environmental footprint of the piping system.

Recycling and Disposal of MDPE Insulation

Proper disposal and recycling of MDPE insulation involve following local regulations and guidelines. Many MDPE products can be recycled, contributing to a circular economy and reducing waste.

Advances in MDPE Pipe Insulation Technology

Recent Innovations and Trends

Recent innovations in MDPE insulation include advancements in material formulations and application techniques. These improvements enhance performance, durability, and ease of installation, keeping pace with evolving industry needs.

Smart Insulation Solutions

Emerging smart insulation solutions incorporate sensors and monitoring technologies to provide real-time data on insulation performance. These innovations allow for proactive maintenance and optimization of energy use.

Future Directions in Insulation Technology

Future trends in insulation technology are likely to focus on greater efficiency, sustainability, and integration with smart systems. Advancements in material science and technology will drive the development of more effective and eco-friendly insulation solutions.

Case Studies and Real-World Examples

Successful Applications of MDPE Insulation

Case studies highlight successful implementations of MDPE pipe insulation across various industries, showcasing its effectiveness in enhancing system performance and durability. These examples provide valuable insights and best practices.

Lessons Learned from Insulation Projects

Lessons learned from real-world projects emphasize the importance of proper installation, maintenance, and adherence to standards. Analyzing these experiences helps in refining practices and achieving better results in future projects.

Conclusion

Summary of Benefits and Techniques

MDPE pipe insulation offers numerous benefits, including enhanced thermal efficiency, reduced energy consumption, and extended pipe lifespan. Understanding and applying the right techniques ensures that your piping systems perform optimally and efficiently.

Final Thoughts on Choosing MDPE Pipe Insulation

Choosing MDPE pipe insulation is a strategic decision for improving system efficiency and durability. By considering the benefits, techniques, and best practices outlined, you can make informed choices that enhance the performance and longevity of your piping systems.

FAQs

What is MDPE pipe insulation?

MDPE pipe insulation is a protective layer made from medium-density polyethylene, designed to wrap around pipes and safeguard them from temperature fluctuations, physical damage, and environmental stressors.

What are the benefits of using MDPE pipe insulation?

MDPE pipe insulation enhances thermal efficiency, reduces heat loss, prevents freezing and pipe bursts, extends pipe lifespan, and offers a cost-effective solution for insulating pipes.

How does MDPE pipe insulation compare to other materials?

MDPE offers superior durability and flexibility compared to materials like polyethylene foam, rubber, and fiberglass. It is more resilient under harsh conditions and easier to handle during installation.

What techniques are used to install MDPE pipe insulation?

Key techniques include selecting the right insulation thickness, applying insulation with pre-slit foam tubes or self-adhesive wraps, and ensuring proper sealing and jointing to prevent gaps and maintain performance.

What maintenance is required for MDPE pipe insulation?

Routine maintenance involves inspecting the insulation for damage, ensuring it remains properly sealed, and addressing any issues such as tears or gaps promptly to maintain optimal performance.

How does MDPE pipe insulation impact the environment?

MDPE insulation is eco-friendly due to its recyclable nature and contribution to energy efficiency. Proper recycling and disposal practices further support environmental sustainability.

What are the recent advances in MDPE pipe insulation technology?

Recent innovations include improved material formulations, smart insulation solutions with real-time monitoring, and advancements in application techniques for better performance and ease of use.