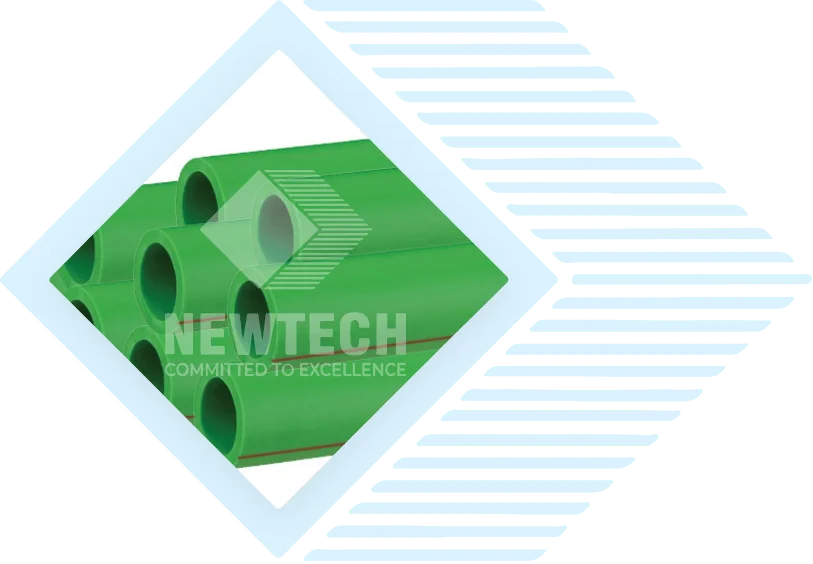

PPRC Pipes & Fittings

PPRC Pipes and Fittings in Pakistan

Master of Poly Random Co-Polymer Pipe

Welcome to Newtech-pipes.com, your premier destination for high-quality PPRC pipes and fittings in Pakistan. PPRC, denoting polypropylene random co-polymer, is pivotal in upholding a building’s structural integrity, emphasizing the foundational role of materials. In this crucial equation, the choice of pipes becomes paramount, with PPRC pipes standing out as a predominant selection, especially for hot and cold-water systems.

In this realm, Newtech Industries (Private) Limited takes center stage as a leading PPRC Pipe manufacturer in Pakistan. Our unwavering commitment to quality serves as the cornerstone for constructing resilient infrastructure, providing developers with the essential tools for success. The superiority of our PPRC pipes not only minimizes vulnerabilities during disasters but also exhibits formidable resistance against potent chemicals, fortifying the bedrock of reliability.

Now, shifting focus to the best and most cost-effective HDPE pipe, it’s imperative to recognize the value of quality and affordability. The best and cheapest HDPE pipe seamlessly integrates these attributes, offering a reliable solution for diverse applications.

Investing in the best and cheapest HDPE pipe ensures a balance between performance and cost-effectiveness, making it the preferred choice for prudent project planners and developers. Consider the best and cheapest HDPE pipe as the cornerstone for cost-efficient yet high-quality piping solutions. This principle applies not only to HDPE pipes but also extends to other essential components, such as Electric Conduit Pipe and MDPE Pipe. These pipes complement the cost-effective approach without compromising on durability and performance, making them integral to budget-friendly yet robust piping systems.

Features of PPRC Pipes:

PPRC (Polypropylene Random Copolymer) pipes are known for their exceptional qualities, making them a preferred choice for various piping applications. Here are the key features of PPRC pipes:

Thermal Stability: PPRC pipes exhibit excellent thermal stability, ensuring consistent performance even under varying temperature conditions.

Corrosion Resistance: Resistant to corrosion, PPRC pipes maintain their integrity over time, making them suitable for diverse environments, including corrosive substances.

Smooth Internal Surface: The pipes boast a smooth internal surface, promoting efficient and uninterrupted fluid flow while minimizing friction.

Low Thermal Conductivity: With low thermal conductivity, PPRC pipes help conserve energy by reducing heat loss in fluid transportation.

Long Service Life: PPRC pipes are known for their durability, offering a long service life and minimizing the need for frequent replacements.

Chemical Resistance: These pipes are resistant to a wide range of chemicals, ensuring suitability for applications involving various fluids and substances.

Environmentally Friendly: PPRC is a recyclable material, aligning with environmental sustainability goals and making PPRC pipes an eco-friendly choice.

Applications of PPRC Pipes about HDPE:

PPRC (Polypropylene Random Copolymer) pipes find diverse applications across various industries, offering distinct advantages similar to those found in HDPE pipes. The versatility of PPRC makes it suitable for several scenarios where the robust features of HDPE are desirable. Here are notable applications of PPRC with a nod to the qualities shared with HDPE pipes:

Water Supply Systems: PPRC pipes, like HDPE pipes, are commonly employed in water supply systems due to their corrosion resistance, smooth internal surface, and long service life.

Heating and Cooling Systems: The excellent thermal stability of PPRC, akin to HDPE, makes it a preferred choice for applications in heating and cooling systems, ensuring efficient energy transfer.

Chemical Handling: PPRC pipes demonstrate resistance to a broad range of chemicals, much like HDPE, making them suitable for handling various fluids and corrosive substances

At Newtech Industries (Private) Limited, we prioritize quality, reliability, and innovation in every aspect of our PPRC pipes and fittings manufacturing process. Our commitment to excellence ensures that our PPRC pipes meet stringent quality standards, offering exceptional durability, corrosion resistance, and thermal stability. With a service lifetime exceeding 50 years and environmentally friendly properties, our PPRC pipes are the ideal choice for a wide range of applications, from water supply systems to chemical handling. Backed by our dedicated customer support team, we are here to provide comprehensive assistance and guidance, ensuring that our clients make informed decisions. Contact us today to experience the superior performance and reliability of Newtech PPRC pipes and fittings.

Why NEWTECH HDPE Pipes?

Newtech Industries (Private) Limited is all about ensuring the best for every organization and individuals who reach them out for the products. Therefore, Polypropylene Random Co-polymer (PPRC) pipes are manufactured according to the process and with the requirements of the certification of quality provided by the government. For the best PPRC Pipes and fittings in Pakistan, reach us anytime through the website, other than that our customer support would love to answer your questions.

Newtech Industries (Private) Limited has the specialty of providing very high-performance results under high and low temperatures and pressure conditions. PPRC Pipes and fittings in Pakistan at NEWTECH-Pipes is quite a reliable choice for everyone because

- A service lifetime of over 50 years.

- Environmentally friendly.

- Chemical stability.

- Creeping strength (Hydrostatic test),

- High-temperature resistance.

- Corrosion Resistant.

- Higher flow capacities.

- Reduces energy losses

- Suitable for potable water and food processing Industries

- Low cost of transportation and handling

- Reduces jointing and labor cost

- Low cost of Fittings used

- Quick & Easy Installation

- A smaller number of fittings are used

- Easy connectivity over a complex network.

The variety of pipes at our company ranges from 63 mm to 110 mm. If you are still unsure about the decision or want to know more details about PPRC Pipes and PPRC pipe prices in Pakistan, our customer support team is out there to help with it.

PPRC Pipe Dimensions Conforming to DIN 8077/8078 Specifications:

Outer Diameter (mm) | PN-10 (for Cold Water) | PN-20 (for Hot & Cold Water) | ||

| Wall Thickness (mm) | Internal Día (mm) | Wall Thickness (mm) | Internal Día (mm) | |

| 20 | 1.9 | 16.2 | 3.4 | 13.2 |

| 25 | 2.3 | 20.4 | 4.2 | 16.6 |

| 32 | 3.0 | 26.0 | 5.4 | 21.2 |

| 40 | 3.7 | 32.6 | 6.7 | 26.6 |

| 50 | 4.6 | 40.8 | 8.4 | 33.2 |

| 63 | 5.8 | 51.4 | 10.5 | 42.0 |

Characteristics of PPRC Material

| Material: | Polypropylene Random Copolymer |

| Durability: | 50 Years |

| Construction: | Satisfactory |

| Connection: | Heat fusion |

| Corrosion: | None |

| Recycling: | Possible |

| Major function: | Cold & hot water supplying pipes, Under floor heating pipes, Chemical |

Comparison of PPRC Pipes with Conventional Pipe Systems

| Pipe Property | G.I. Pipe | Copper Pipe | UPVC Pipe | PPRC Pipe |

| Service life | 5-10 Years | 50 Years | 30 Years | 50 Years |

| Resistance to High Temperature | Good | Good | Bad | Good |

| Hygienic Property | Bad | Common | Bad | Good |

| Recyclable and No Pollution | No | No | No | Yes |

| Pipe Furring | Yes | Yes | No | No |

| Corrosion-Resistant | Bad | Bad | Good | Good |

| Installation | Hard | Hard | Easy | Easy |

| Price | Low | High | Low | Common |

| Reliability | Common | Common | Common | Good |

A1: PPRC stands for Polypropylene Random Copolymer, a type of plastic widely used in the manufacturing of pipes and fittings.

A2: PPRC pipes offer advantages such as corrosion resistance, thermal stability, smooth internal surfaces, and ease of installation, making them ideal for various applications.

A3: Yes, PPRC pipes are commonly used in water supply systems due to their corrosion resistance, ensuring the delivery of clean and safe water.

A4: PPRC pipes are known for their durability and long service life, making them a reliable choice in comparison to other materials.

A5: Yes, PPRC pipes exhibit resistance to harsh weather conditions, making them suitable for diverse climates in Pakistan.

A6: Generally, it is recommended to use fittings from the same manufacturer to ensure compatibility and optimal performance.

A7: PPRC pipes and fittings find widespread use in water supply, heating and cooling systems, industrial processes, and construction projects across Pakistan.

A8: Yes, PPRC is a recyclable material, contributing to environmental sustainability and aligning with eco-friendly practices.

A9: Yes, PPRC pipes are resistant to a variety of chemicals, making them suitable for applications involving different fluids and substances.

A10: PPRC pipes are typically installed using heat fusion techniques, ensuring secure and leak-free joints. Proper installation procedures as per manufacturer guidelines are recommended for optimal performance.