MDPE Pipes Suppliers

“MDPE,” or “Medium-Density Polyethylene,” is aptly named for its value falling within the 0.926-0.940g/cm3 range, placing it in the medium-density category. The manufacturing process of MDPE involves catalysts such as Ziegler-Natta, chromium/silica catalysts, and metallocene catalysts. This material boasts excellent chemical resistance and remains highly stable at room temperature, with no dissolution occurring at standard environmental conditions.

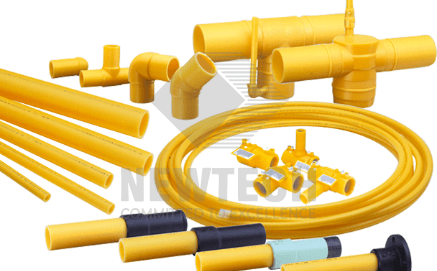

For your piping needs, Newtech Industries is your go-to source for the best and highest-quality MDPE Pipes and Fittings in Pakistan. Alongside our expertise in MDPE, we recognize the importance of the best and cheapest HDPE PIPE in various applications. NEWTECH ensures that our HDPE pipes not only meet high standards but also provide a cost-effective solution for your projects.